Vacuum forming is a widely used manufacturing process that transforms plastic sheets into various shapes and products by heating the plastic until it becomes pliable, then using a vacuum to pull it over a mold. This method is particularly cost-effective for low to medium production runs and is commonly used in industries like packaging, automotive, and consumer goods. The success of vacuum forming1 largely depends on selecting the right type of plastic, as different materials offer unique properties suited to specific applications.

Vacuum forming heats a plastic sheet, stretches it over a mold, and uses a vacuum to shape it, ideal for simple to moderately complex parts like packaging or automotive components.

This article explores the types of plastics that can be used in vacuum forming, providing insights into their properties, applications, and how to choose the best material for your project. Whether you're new to vacuum forming or looking to optimize your material selection, this guide will help you make informed decisions.

Vacuum forming is only suitable for low-volume production.False

While cost-effective for low to medium runs, vacuum forming can also be used for higher volumes with the right setup.

All plastics can be used in vacuum forming.False

Only thermoplastics, which can be reshaped when heated, are suitable for vacuum forming.

What Are the Common Plastics Used in Vacuum Forming?

Vacuum forming relies on thermoplastics2, which can be heated and reshaped multiple times. Each plastic has distinct properties that make it suitable for specific applications.

Common plastics for vacuum forming include ABS, acrylic (PMMA), PETG, HIPS, PVC, polycarbonate (PC), and HDPE, each chosen for properties like durability, clarity, or cost-effectiveness.

| Plastic Type | Key Properties | Typical Applications |

|---|---|---|

| ABS | Tough, impact-resistant | Machine housings, automotive parts |

| Acrylic (PMMA) | Clear, brittle, weather-resistant | Signs, displays, skylights |

| PETG | Food-safe, strong, sterilizable | Medical trays, food packaging |

| HIPS | Affordable, versatile | Toys, packaging, displays |

| PVC | Chemical-resistant, flame-retardant | Packaging, car trims |

| Polycarbonate (PC) | Very strong, clear, heat-resistant | Safety shields, skylights |

| HDPE | Durable, chemical-resistant | Containers, outdoor parts |

Acrylonitrile Butadiene Styrene (ABS)

ABS is a popular choice for vacuum forming due to its toughness and impact resistance. It’s widely used in automotive parts, machine housings, and consumer goods like toys. ABS can be easily painted or printed on, making it versatile for various finishes.

Acrylic (PMMA)

Acrylic, or polymethyl methacrylate (PMMA), is known for its clarity and brittleness. It’s ideal for applications where transparency is important, such as signs, displays, and light diffusers. However, it’s less stretchy and requires careful temperature control during forming.

Polyethylene Terephthalate Glycol (PETG)

PETG is a food-safe plastic3 with high impact strength and clarity. It’s commonly used in medical trays, food containers, and point-of-sale displays. PETG is highly formable and suitable for applications requiring sterilization.

High-Impact Polystyrene (HIPS)

HIPS is an affordable and versatile plastic, making it a go-to for toys, packaging, and displays. It’s easy to form and can be finished with various textures, paints, or prints.

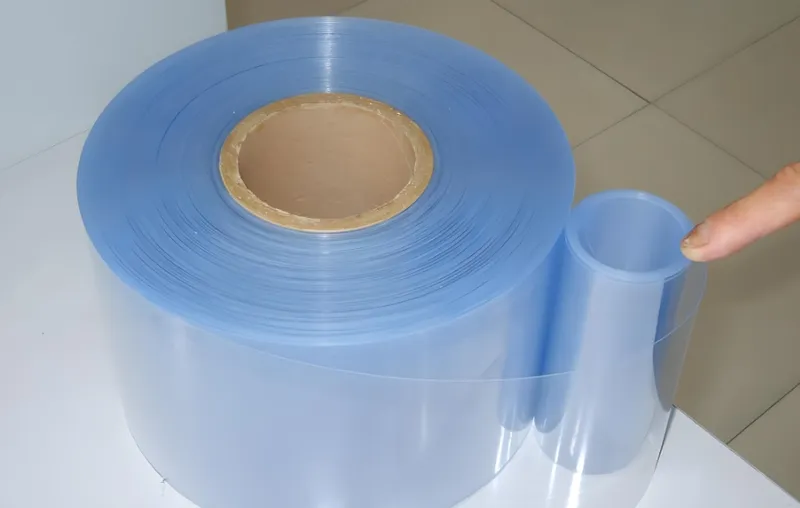

Polyvinyl Chloride (PVC)

PVC is chemical-resistant and flame-retardant, making it suitable for packaging, car trims, and machine guards. It’s easy to form in thin gauges but may require specialist inks for printing.

Polycarbonate (PC)

Polycarbonate is extremely strong, clear, and heat-resistant, making it ideal for safety shields, skylights, and aircraft trim. It requires higher forming temperatures but offers excellent detail retention.

High-Density Polyethylene (HDPE)

HDPE is durable and chemical-resistant, often used for containers, outdoor parts, and vehicle components. It has high shrinkage, so careful tolerance control is needed during forming.

ABS is the most commonly used plastic in vacuum forming.True

ABS is favored for its balance of strength, ease of forming, and versatility across industries.

Acrylic is unsuitable for outdoor applications.False

Acrylic has good weather resistance, making it suitable for outdoor signs and displays.

Why Choose Vacuum Forming Over Other Methods?

Vacuum forming offers several advantages, especially for specific production needs and design requirements.

Vacuum forming is cost-effective for low to medium production runs4, allows quick design changes, and is ideal for large, simple to moderately complex parts.

| Comparison | Pros of Vacuum Forming | Cons of Vacuum Forming |

|---|---|---|

| Vs. Injection Molding | Lower tooling costs, faster setup | Less precise for highly detailed parts |

| Vs. 3D Printing | Better for larger parts, more cost-effective for medium runs | Slower for very low-volume prototypes |

| Vs. Pressure Forming | Simpler and cheaper for shallow parts | Less detail than pressure forming |

Additional Benefits:

- Consistency: The same mold ensures repeatable results.

-

Single-Piece Construction: Produces seamless parts, enhancing durability.

-

Material Efficiency: Uses less material than other methods for similar parts.

However, vacuum forming may require post-processing like trimming or painting, which can add to the overall cost and time.

Vacuum forming is always cheaper than injection molding.False

For very high production volumes, injection molding may be more cost-effective due to economies of scale.

Vacuum forming can produce parts with the same level of detail as injection molding.False

Injection molding allows for finer details and more complex geometries.

How to Choose the Right Plastic for Your Project?

Selecting the appropriate plastic depends on several factors, including cost, durability, environmental resistance5, and regulatory requirements.

Choose plastics based on project needs: cost6 (HIPS, PVC), durability7 (ABS, PC), clarity8 (acrylic, PETG), or environmental resistance (HDPE, PC).

Cost Considerations

For budget-conscious projects, HIPS and PVC are low-cost options9. They are suitable for applications where high strength or special properties are not required, such as disposable packaging or simple displays.

Durability and Strength

If your project requires tough, impact-resistant parts10, ABS or polycarbonate are better choices. These materials are ideal for automotive components, machine housings, or safety equipment.

Clarity and Aesthetics

For applications where transparency is important, such as signs or displays, acrylic or PETG are excellent options. Polycarbonate also offers clarity but is stronger and more heat-resistant.

Environmental Resistance

For outdoor use or exposure to chemicals, HDPE or polycarbonate are more suitable due to their durability and resistance to UV light and chemicals.

Regulatory Compliance

If your project involves food contact or medical applications, PETG is a safe choice as it is FDA-approved11 and sterilizable.

Material choice in vacuum forming is solely based on cost.False

While cost is important, factors like strength, clarity, and environmental resistance also play a crucial role.

All vacuum forming plastics are food-safe.False

Only specific plastics like PETG and certain grades of PVC are approved for food contact.

Conclusion

Vacuum forming is a versatile and cost-effective manufacturing process suitable for a wide range of applications, from packaging to automotive parts. By understanding the properties of different plastics—such as ABS, acrylic, PETG, HIPS, PVC, polycarbonate, and HDPE—you can select the right material for your project based on factors like cost, durability, clarity, and environmental resistance.

-

Explore this resource to understand the vacuum forming process and its applications in various industries, enhancing your knowledge of manufacturing techniques. ↩

-

Learn about thermoplastics and their role in vacuum forming, which is crucial for selecting the right materials for your projects. ↩

-

Learn about food-safe plastics, their properties, and applications in food packaging and medical fields, ensuring safety and compliance. ↩

-

Explore how cost-effective production methods can enhance your manufacturing efficiency and reduce expenses. ↩

-

Discover which plastics provide superior environmental resistance, ensuring durability and longevity in various applications. ↩

-

Explore this link to discover budget-friendly plastic options that meet your project needs without compromising quality. ↩

-

Learn about the strongest plastics available for your projects, ensuring longevity and reliability in your applications. ↩

-

Find out which transparent plastics are ideal for aesthetic applications, enhancing visibility and design in your projects. ↩

-

Exploring this resource will help you understand how low-cost materials can optimize your budget without compromising quality. ↩

-

Discovering this information can guide you in selecting the right materials for durability and safety in your projects. ↩

-

This link will provide insights into the importance of FDA approval for safety in food-related projects. ↩