The thermoforming heating process is a critical step in shaping thermoplastic sheets1 into desired forms by making them pliable through heat. Understanding the various heating methods is essential for optimizing production, ensuring quality, and selecting the right approach for specific applications.

Thermoforming heating methods include radiation, convection, conduction, catalytic gas, halogen, and microwave, each offering unique advantages for different materials and production needs, such as speed, precision, and cost-efficiency.

Mastering these heating techniques2 can significantly impact the efficiency and quality of your thermoforming operations. Explore further to understand how each method affects material behavior and product outcomes.

Radiation heating is the most common method in thermoforming.True

Radiation, particularly infrared heating, is widely used due to its fast heat-up times and ability to precisely control temperature zones.

All thermoforming heating methods are equally effective for all materials.False

Different materials require specific heating methods to achieve optimal pliability and avoid degradation, making method selection crucial.

- 1. What are the Common Methods of Thermoforming Heating?

- 2. What are the Steps in the Thermoforming Heating Process?

- 3. What are the Key Factors in Selecting a Thermoforming Heating Method?

- 4. What are the Applications of Thermoforming Heating Methods?

- 5. How Do Thermoforming Heating Methods Compare to Other Technologies?

- 6. Conclusion

What are the Common Methods of Thermoforming Heating?

Thermoforming heating methods3 are essential for preparing thermoplastic sheets for molding, each offering distinct benefits and suited to specific applications.

Common thermoforming heating methods include radiation (infrared), convection (hot air), conduction (contact), catalytic gas, halogen, and microwave, chosen based on material, thickness, and production needs.

| Heating Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| Radiation | Uses infrared or quartz heaters to heat the sheet without contact. | Fast heat-up, precise zoning. | Fragile elements, high cost. |

| Convection | Employs hot air ovens to circulate heat around the sheet. | Stable heat, easy installation. | Slow response, large footprint. |

| Conduction | Direct contact with hot rollers or panels to transfer heat. | Durable, precise control. | High installation cost, energy-intensive. |

| Catalytic Gas | Uses gas to provide uniform heat with low operating costs. | Inexpensive energy, durable. | Slow response, high installation cost. |

| Halogen | Provides pulsed heat with rapid heat-up using small elements. | Fastest heat-up, precise zoning. | Fragile, very expensive. |

| Microwave | Used for specific composites, offering better temperature distribution. | Uniform heating. | Limited to specific materials. |

Radiation Heating

Radiation heating4, particularly using infrared heaters, is the most prevalent method in thermoforming. It allows for rapid heating and precise control over temperature zones, making it ideal for high-volume production. For example, in packaging applications, infrared heating is often used to quickly heat thin-gauge sheets of PET or PVC. However, the heaters can be fragile and expensive to install.

Convection Heating

Convection heating5, typically via hot air ovens, is favored for preheating thick sheets or for applications requiring stable, uniform heat. This method is slower but provides consistent temperature distribution, which is crucial for materials like ABS used in automotive parts. The downside is the slower response time and the larger space required for ovens.

Conduction Heating

Conduction heating involves direct contact with hot surfaces, such as rollers or panels. This method offers excellent temperature control and durability, making it suitable for precision applications like medical device manufacturing. However, it is energy-intensive and costly to set up.

Catalytic Gas Heating

Catalytic gas heating provides uniform heat with low operating costs, making it a cost-effective option for heavy-gauge sheets used in structural components. Its slow temperature response, however, limits its use in high-speed production environments.

Halogen Heating

Halogen heating delivers pulsed heat with the fastest heat-up times, ideal for specialized applications requiring rapid cycling. Despite its speed and precision, the high cost and fragility of halogen elements restrict its widespread adoption.

Microwave Heating

Microwave heating is used for specific composites, such as wood/polypropylene, offering superior temperature distribution. Its application is limited to materials that can absorb microwave energy effectively.

Radiation heating is the most versatile method for all thermoforming applications.False

While radiation heating is widely used, other methods like conduction or convection may be more suitable for specific materials or production requirements.

Conduction heating is the most energy-efficient method.False

Conduction heating can be energy-intensive due to the direct contact required, making it less efficient than methods like radiation or catalytic gas in certain scenarios.

What are the Steps in the Thermoforming Heating Process?

The thermoforming heating process is a crucial phase in preparing thermoplastic sheets for molding, ensuring they reach the optimal temperature for forming.

The thermoforming heating process involves selecting the heating method, setting temperature and time, heating the sheet, and monitoring for uniform pliability before forming.

Selecting the Heating Method

Choose the appropriate heating method6 based on the material, sheet thickness, and production requirements. For instance, radiation heating is ideal for thin sheets, while convection is better for thicker materials.

Setting Temperature and Time

Determine the optimal heating temperature and duration based on the material's properties. For example, PLA typically requires heating to 80–110°C, while ABS may need higher temperatures. The heating time varies with sheet thickness and the chosen method.

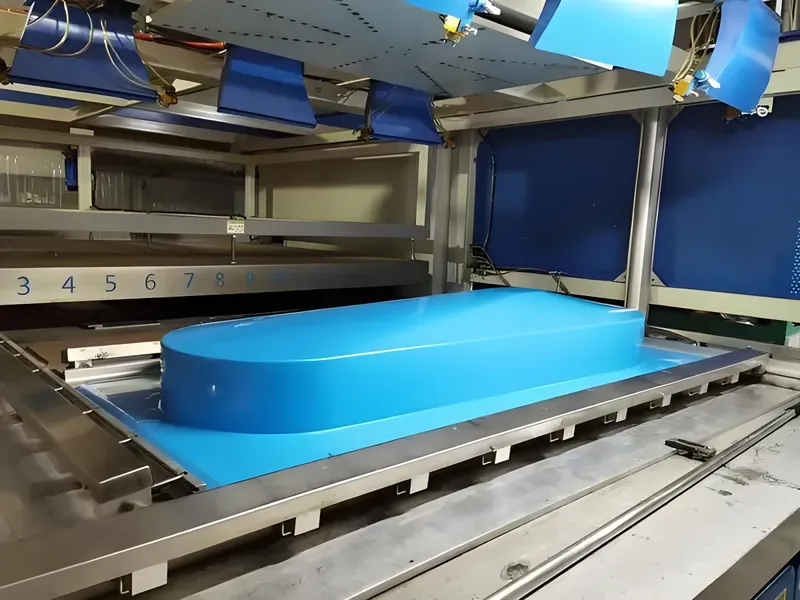

Heating the Sheet

Apply heat using the selected method. In radiation heating, infrared heaters are positioned to evenly heat the sheet. For convection, hot air is circulated around the sheet. Conduction involves direct contact with heated surfaces.

Monitoring for Uniformity

Ensure the sheet reaches a uniform temperature7 across its surface to prevent defects during forming. Techniques like zoning in radiation heating or rotating the sheet in convection ovens can help achieve this.

Transition to Forming

Once the sheet is pliable, it is quickly transferred to the forming station to prevent cooling. The timing is critical to maintain the sheet's temperature within the forming window.

All heating methods require the same temperature settings for a given material.False

Different heating methods may require adjustments in temperature settings due to variations in heat transfer efficiency.

Uniform heating is critical for preventing defects in thermoformed parts.True

Uneven heating can lead to inconsistencies in material thickness and shape, resulting in defective products.

What are the Key Factors in Selecting a Thermoforming Heating Method?

Choosing the right heating method is essential for optimizing the thermoforming process, impacting efficiency, quality, and cost.

Key factors in selecting a thermoforming heating method include material type, sheet thickness8, production speed, energy efficiency9, and cost considerations.

Material Type

Different thermoplastics have varying heating requirements. For example, PET benefits from radiation heating due to its transparency, while ABS may require convection for uniform heat distribution.

Sheet Thickness

Thinner sheets heat quickly and are suited to radiation or halogen heating, whereas thicker sheets may need convection or conduction for thorough heating.

Production Speed

High-volume production often favors radiation or halogen heating for their rapid heat-up times. Slower methods like catalytic gas are better for lower-volume, specialized applications.

Energy Efficiency

Methods like catalytic gas offer low operating costs, making them attractive for energy-conscious operations. Conduction, while precise, can be more energy-intensive.

Cost Considerations

Initial installation costs vary, with radiation and halogen being expensive to set up but offering long-term efficiency. Convection and catalytic gas may have lower upfront costs but higher operational expenses.

Material type is the only factor to consider when selecting a heating method.False

While material type is crucial, other factors like sheet thickness and production speed also significantly influence the choice of heating method.

Energy efficiency is a critical factor in reducing operational costs in thermoforming.True

Selecting an energy-efficient heating method can lead to substantial cost savings over time, especially in high-volume production.

What are the Applications of Thermoforming Heating Methods?

Thermoforming heating methods are integral to producing a wide range of products across various industries, each method tailored to specific applications.

Thermoforming heating methods are used in packaging, automotive, medical, and consumer goods industries, with applications ranging from food trays to automotive panels.

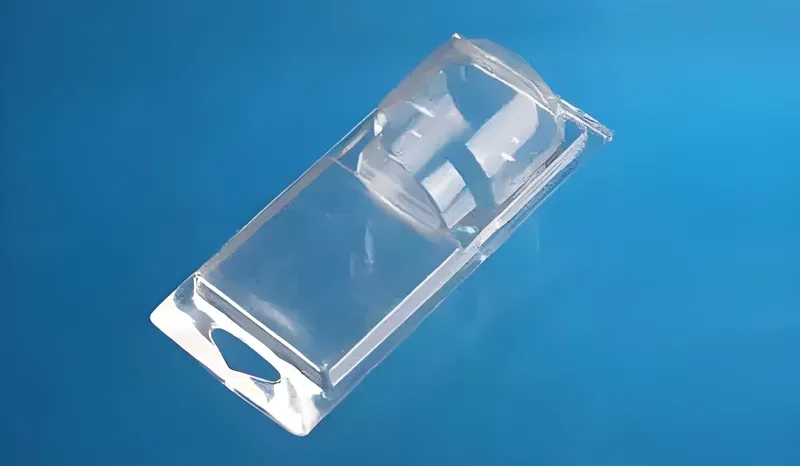

Packaging

Radiation heating is commonly used for thin-gauge sheets in packaging applications, such as food trays and blister packs, due to its speed and efficiency.

Automotive

Convection heating is often employed for thicker sheets used in automotive parts like dashboards and interior panels, ensuring uniform heat distribution for consistent quality.

Medical

Conduction heating provides the precision needed for medical device components, where tight tolerances and material integrity are critical.

Consumer Goods

Halogen heating, with its rapid heat-up, is suitable for specialized consumer products requiring quick production cycles, such as custom appliance housings.

Thermoforming is only used in the packaging industry.False

Thermoforming is utilized across multiple industries, including automotive, medical, and consumer goods, for a variety of applications.

Radiation heating is the preferred method for all thermoforming applications.False

While radiation heating is popular, other methods like convection or conduction are better suited for specific applications and materials.

How Do Thermoforming Heating Methods Compare to Other Technologies?

Understanding how thermoforming heating methods compare to other manufacturing technologies can help in selecting the most appropriate process for a given application.

Thermoforming heating methods offer advantages in cost, speed, and material versatility compared to technologies like injection molding, but may lack precision for complex geometries.

Thermoforming vs. Injection Molding

Thermoforming is more cost-effective for low to medium volumes10 and large parts, with lower tooling costs. Injection molding, however, provides higher precision for complex shapes11 and is better for high-volume production.

Thermoforming vs. Blow Molding

Blow molding is ideal for hollow parts like bottles, while thermoforming is better for open-shaped products like trays and panels.

Thermoforming vs. Rotational Molding

Rotational molding is suited for large, hollow parts with uniform wall thickness, whereas thermoforming is more versatile for a range of shapes and sizes.

Thermoforming is always the best choice for plastic part production.False

While thermoforming has many advantages, other technologies like injection molding or blow molding may be more suitable depending on the specific requirements of the part.

Thermoforming offers lower tooling costs compared to injection molding.True

Thermoforming molds are generally less expensive to produce than injection molds, making it a cost-effective option for smaller production runs.

Conclusion

Thermoforming heating methods are diverse, each with unique strengths tailored to specific materials, applications, and production needs. Radiation heating, with its speed and precision, is ideal for high-volume packaging, while convection and conduction offer stability and control for thicker materials in automotive and medical applications. Understanding these methods' nuances—from energy efficiency to cost implications—empowers manufacturers to optimize their processes. As thermoforming continues to evolve, selecting the right heating method remains a cornerstone of achieving high-quality, cost-effective production.

-

Explore the properties and applications of thermoplastic sheets to better understand their role in thermoforming processes. ↩

-

Learn how mastering heating techniques can enhance efficiency and quality in thermoforming operations. ↩

-

Explore this resource to understand the various thermoforming heating methods and their specific applications, enhancing your knowledge in the field. ↩

-

Discover the mechanics and advantages of radiation heating, a key method in thermoforming, to optimize your production processes. ↩

-

Learn about convection heating's benefits and drawbacks to make informed decisions for your thermoforming projects. ↩

-

Different heating methods can significantly impact the quality of the molded product. Discover the best practices and techniques for effective heating methods. ↩

-

Achieving a uniform temperature is crucial to prevent defects in the final product. Learn more about its significance and how to monitor it effectively. ↩

-

Discover how sheet thickness influences the choice of heating methods, ensuring you select the best approach for your specific materials. ↩

-

Learn about the importance of energy efficiency in heating methods, which can significantly reduce operational costs in thermoforming processes. ↩

-

Discover insights on how thermoforming can save costs in production, especially for low to medium volume needs, making it a smart choice. ↩

-

Learn about the precision capabilities of injection molding, which can be crucial for projects requiring intricate designs and high accuracy. ↩