Thermoforming is a versatile manufacturing process that transforms plastic sheets into a wide range of products, from packaging to automotive components. One of the critical factors in thermoforming is the thickness of the plastic sheet, as it directly impacts the process parameters, material behavior, and the final product's properties. This article explores the maximum and minimum thicknesses of thermoformed sheets1, delving into definitions, classifications, applications, technical aspects, and practical tools to guide your decision-making.

Thermoformed sheets typically range from 0.010 inches (0.254 mm) to 1 inch (25.4 mm) in thickness, with thin-gauge sheets used for lightweight packaging and thick-gauge for durable, structural components.

Understanding the appropriate sheet thickness is essential for optimizing the thermoforming process and ensuring the final product meets your requirements. Explore further to learn how different thicknesses impact applications, material choices, and process parameters.

Thermoforming can handle sheets up to 1 inch thick.True

With specialized equipment, some manufacturers can process sheets up to 1 inch thick for thick-gauge applications, as noted by Global Thermoforming.

Thin-gauge thermoforming is only for packaging.False

While packaging is a primary application, thin-gauge thermoforming is also used for products like disposable trays, inserts, and lightweight components in various industries.

- 1. What are the Common Thickness Ranges in Thermoforming?

- 2. What are the Steps in the Thermoforming Process?

- 3. What Factors Influence the Choice of Sheet Thickness in Thermoforming?

- 4. What are the Applications of Different Sheet Thicknesses in Thermoforming?

- 5. How Do Material Choices Affect Sheet Thickness in Thermoforming?

- 6. What are the Differences Between Thin-Gauge and Thick-Gauge Thermoforming?

- 7. Conclusion

What are the Common Thickness Ranges in Thermoforming?

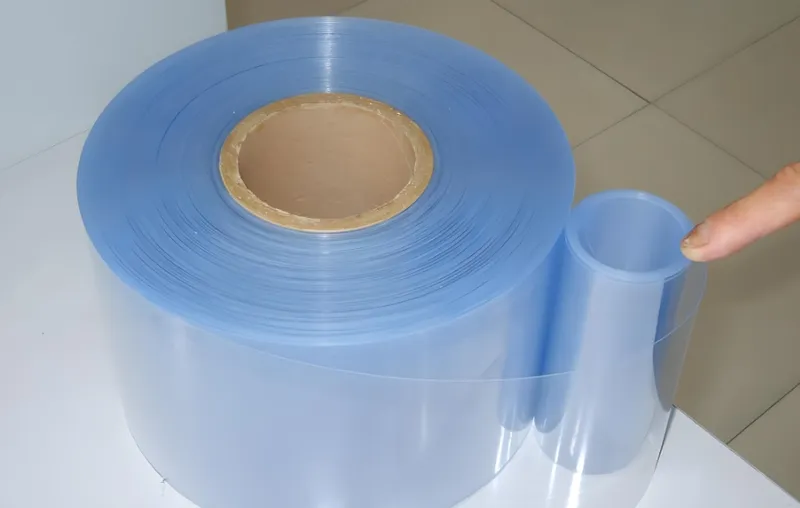

Thermoforming sheet thicknesses are categorized into thin-gauge and thick-gauge, each serving distinct purposes based on the required strength, durability, and application.

Thermoformed sheets range from 0.010 inches (0.254 mm) for thin-gauge applications like packaging to 1 inch (25.4 mm) for thick-gauge structural components, depending on the material and process.

| Type | Thickness Range | Typical Applications |

|---|---|---|

| Thin-gauge | 0.010–0.060 inches (0.254–1.524 mm) | Blister packs, food trays, medical packaging |

| Thick-gauge | >0.060 inches, up to 1 inch (25.4 mm) | Automotive panels, appliance housings, enclosures |

Thin-Gauge Thermoforming

Thin-gauge thermoforming typically involves sheets ranging from 0.010 to 0.060 inches. These sheets are often used for lightweight, disposable products such as blister packs, clamshells, and food trays. The process is ideal for high-volume production due to its speed and cost-efficiency.

Thick-Gauge Thermoforming

Thick-gauge thermoforming uses sheets thicker than 0.060 inches, with some processes handling up to 1 inch or more. This type is suited for durable, structural components like automotive interior panels, medical device enclosures, and large containers, where strength and rigidity are essential.

Thin-gauge thermoforming is limited to shallow draws.True

Thin sheets are less capable of handling deep draws due to material thinning, making them better suited for simpler shapes.

Thick-gauge thermoforming can achieve complex geometries with deep draws.True

Thicker sheets allow for deeper draws (up to 3:1 depth-to-diameter ratio) and more intricate designs, as they maintain structural integrity during forming.

What are the Steps in the Thermoforming Process?

The thermoforming process2 is crucial for producing parts with varying thicknesses, and understanding each step helps in selecting the appropriate sheet thickness for your application.

The thermoforming process involves heating a plastic sheet, forming it over a mold using vacuum, pressure, or mechanical means, cooling it, and trimming the excess material, with sheet thickness3 influencing each step.

Material Selection

Choose a thermoplastic material4 based on the application. Common materials include PET and PVC for thin-gauge and ABS and PC for thick-gauge.

Sheet Preparation

Cut or roll the sheet to the required size, ensuring uniformity for consistent heating and forming.

Heating

Uniformly heat the sheet to its forming temperature. Thicker sheets require longer heating times to ensure even temperature distribution.

Forming

Use vacuum, pressure, or mechanical assistance to stretch the sheet over the mold. Thicker sheets can handle deeper draws and more complex shapes.

Cooling

Allow the formed part to cool and solidify on the mold. Thicker parts may require longer cooling times.

Trimming

Remove excess material to obtain the final part. Secondary operations like drilling or assembly may follow.

Thicker sheets require more heating time in thermoforming.True

Thicker sheets need additional time to heat uniformly, ensuring proper forming without defects.

Thermoforming always results in uniform wall thickness.False

Wall thickness can vary depending on the draw depth and mold design, with thinning occurring in areas of greater stretch.

What Factors Influence the Choice of Sheet Thickness in Thermoforming?

Selecting the right sheet thickness is critical for achieving the desired performance and cost-efficiency in thermoformed products.

Sheet thickness in thermoforming is influenced by the required strength, part complexity, material properties, and production volume, with thicker sheets offering durability and thinner sheets providing cost savings.

Required Strength and Durability

Thicker sheets provide greater strength and impact resistance, making them suitable for structural applications. Thin sheets are ideal for lightweight, disposable products.

Part Complexity and Draw Depth

Thicker sheets can accommodate deeper draws (up to 3:1 depth-to-diameter ratio) and more complex geometries, while thin sheets are limited to shallower shapes.

Material Properties

Different materials have varying forming capabilities. For example, PET is flexible and suited for thin-gauge, while ABS is rigid and better for thick-gauge.

Production Volume

Thin-gauge thermoforming is more cost-effective for high-volume production due to faster cycle times, while thick-gauge is better for lower-volume, high-durability parts.

Thicker sheets are always more expensive to process.True

Thicker sheets require more material, longer heating and cooling times, and specialized equipment, increasing production costs.

Thin sheets cannot be used for structural components.True

Thin sheets lack the rigidity and strength needed for structural applications, making them unsuitable for such uses.

What are the Applications of Different Sheet Thicknesses in Thermoforming?

Thermoforming serves a wide range of industries, with sheet thickness determining the suitability for specific applications.

Thin-gauge thermoforming is used for packaging and disposable items, while thick-gauge is employed for durable components in automotive, medical, and industrial sectors.

Packaging Industry

Thin-gauge sheets (0.010–0.060 inches) are commonly used for blister packs, clamshells, and food trays due to their lightweight and cost-effective nature.

Automotive Industry

Thick-gauge sheets (up to 1 inch) are used for interior panels, dashboards, and exterior components, providing durability and impact resistance.

Medical Industry

Thick-gauge thermoforming produces enclosures for medical devices and equipment housings, where strength and precision are critical.

Consumer Goods

Both thin and thick-gauge sheets are used, with thin sheets for disposable trays and thick sheets for durable products like refrigerator liners.

Thermoforming is widely used in the automotive industry for lightweight components.True

Thick-gauge thermoforming produces lightweight yet durable parts, reducing vehicle weight and improving fuel efficiency.

Thin-gauge thermoforming is unsuitable for high-volume production.False

Thin-gauge thermoforming is ideal for high-volume production due to its fast cycle times and lower material costs.

How Do Material Choices Affect Sheet Thickness in Thermoforming?

Material selection plays a crucial role in determining the suitable thickness range for thermoformed sheets, as different plastics have unique forming properties.

Materials like PET and PVC are ideal for thin-gauge thermoforming[^5], while ABS and PC are better suited for thick-gauge applications due to their strength and rigidity.

| Material | Suitable for Thin-gauge | Suitable for Thick-gauge | Notes |

|---|---|---|---|

| PET | Yes | No | Flexible, good for packaging |

| PVC | Yes | No | Versatile, used in various industries |

| ABS | No | Yes | Strong, impact-resistant |

| PC | No | Yes | High strength, used in medical and automotive |

Amorphous Materials

Materials like PET and PC have broader forming temperature ranges, making them easier to thermoform. PET is commonly used in thin-gauge for packaging, while PC is used in thick-gauge for its strength.

Semi-Crystalline Materials

Materials like PP and HDPE require precise temperature control due to narrower forming windows. They are often used in thick-gauge applications5 where durability is needed.

All thermoplastics can be thermoformed at any thickness.False

Each material has a specific thickness range where it performs optimally, influenced by its forming temperature and physical properties.

Material selection impacts the maximum achievable sheet thickness.True

Some materials, like ABS, can be thermoformed at greater thicknesses due to their rigidity, while others, like PET, are limited to thinner sheets.

What are the Differences Between Thin-Gauge and Thick-Gauge Thermoforming?

Understanding the distinctions between thin-gauge and thick-gauge thermoforming is essential for selecting the right process for your project.

Thin-gauge thermoforming uses sheets from 0.010 to 0.060 inches for lightweight, high-volume products, while thick-gauge uses sheets over 0.060 inches for durable, structural components.

| Aspect | Thin-gauge | Thick-gauge |

|---|---|---|

| Thickness Range | 0.010–0.060 inches | >0.060 inches, up to 1 inch |

| Production Cycle | 3-10 seconds per part | 3-10 minutes per part |

| Material Cost | Lower | Higher |

| Durability | Less durable, often disposable | More durable, structural |

| Complexity | Suitable for simple shapes | Handles complex geometries, deep draws |

Process Characteristics

Thin-gauge thermoforming is typically roll-fed and automated, allowing for rapid production of large quantities. Thick-gauge is sheet-fed, with longer cycle times but greater flexibility in part design.

Application Suitability

Thin-gauge is best for simple, shallow parts like packaging, while thick-gauge excels in producing complex, deep-drawn parts with undercuts, such as automotive components.

Thin-gauge thermoforming is more cost-effective for large production runs.True

The faster cycle times and lower material usage make thin-gauge ideal for high-volume production.

Thick-gauge thermoforming cannot produce lightweight parts.False

While thicker, these parts are still lighter than alternatives like metal, and the process allows for weight reduction through design optimization.

Conclusion

Thermoforming is a highly adaptable process, with sheet thicknesses ranging from 0.010 inches for thin-gauge applications to 1 inch for thick-gauge structural components6. Selecting the right thickness depends on factors like required strength, part complexity, material properties, and production volume. Thin-gauge thermoforming is ideal for lightweight, high-volume products such as packaging, while thick-gauge is suited for durable, complex parts in industries like automotive and medical.

By understanding the capabilities and limitations of different sheet thicknesses, manufacturers can optimize their thermoforming processes for efficiency, cost savings, and product quality.

-

Discover the various applications and benefits of thermoformed sheets in manufacturing, enhancing your understanding of this versatile process. ↩

-

Explore this link to gain a deeper understanding of the thermoforming process, its steps, and applications in manufacturing. ↩

-

Learn how sheet thickness impacts the thermoforming process, influencing heating, forming, and cooling for optimal results. ↩

-

Discover the various thermoplastic materials available and their specific applications to make informed choices for your projects. ↩

-

Learning about thick-gauge applications can help you understand their importance in producing durable and strong products. ↩

-

Learn how thick-gauge components are crucial for durability and complexity in key industries. ↩