Thermoforming is a versatile manufacturing process where a plastic sheet is heated to a pliable forming temperature, shaped using a mold, and trimmed to create a usable product. This technique is widely adopted across industries like packaging, automotive, medical, and consumer goods due to its cost-effectiveness and flexibility. The mold is a pivotal element in thermoforming, dictating the shape, quality, and functionality of the final product. In this blog post, we’ll dive into the different types of thermoforming molds1, their applications, and how they stack up against other manufacturing technologies.

- 1. What Are the Common Types of Thermoforming Molds?

- 2. What Materials Are Used for Thermoforming Molds?

- 3. What Are the Applications of Thermoforming Molds?

- 4. How Does Thermoforming Compare to Other Technologies?

- 5. What Are the Key Steps in the Thermoforming Process?

- 6. What Are the Common Materials Used in Thermoforming?

- 7. What Are the Best Practices for Designing Thermoforming Molds?

- 8. Conclusion

What Are the Common Types of Thermoforming Molds?

Thermoforming molds shape heated plastic sheets into precise forms, and they vary based on the forming method, application, and desired outcome. The three primary types are vacuum forming2, pressure forming, and mechanical forming molds, each tailored to specific production needs.

Thermoforming molds include vacuum forming, pressure forming3, and mechanical forming types, each excelling in applications ranging from simple packaging to intricate automotive parts.

| Mold Type | Process | Applications | Advantages |

|---|---|---|---|

| Vacuum Forming | Vacuum pressure | Packaging trays, disposable cups | Cost-effective, large production runs |

| Pressure Forming | Air pressure | Automotive dashboards, appliance housings | High-quality finish, tight tolerances |

| Mechanical Forming4 | Physical force | Deep draw parts, complex geometries | Precise control, versatile shaping |

Vacuum Forming Molds

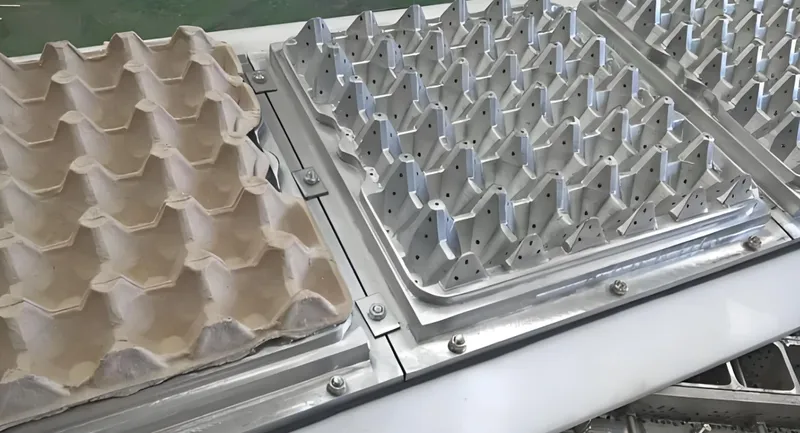

Vacuum forming molds utilize vacuum pressure to draw a heated plastic sheet onto the mold’s surface, forming the desired shape. This method shines in creating shallow parts with straightforward designs, such as packaging trays, disposable cups, and lids. Its affordability and efficiency make it a go-to for large-scale production.

Pressure Forming Molds

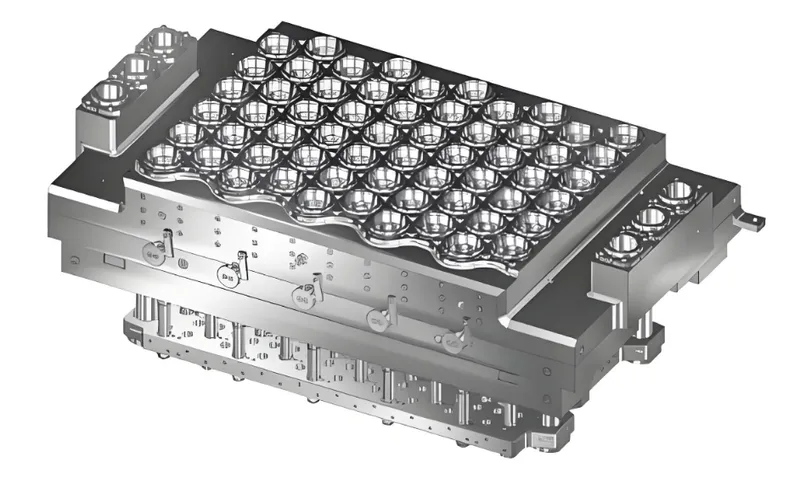

Pressure forming molds employ air pressure to press the heated plastic sheet into the mold, enabling more detailed and intricate shapes. Ideal for parts needing a superior surface finish—like automotive dashboards, appliance housings, and medical device components—this method offers tighter tolerances and enhanced feature definition compared to vacuum forming.

Mechanical Forming Molds

Mechanical forming molds rely on physical force, often via plugs or matched dies, to shape the plastic sheet. This approach suits applications requiring precise control, such as deep-draw parts or complex geometries. It can be paired with vacuum or pressure forming for optimal results.

Vacuum forming molds are the most cost-effective option for all thermoforming applications.False

While vacuum forming molds excel in cost-effectiveness for large runs of simple parts, pressure forming molds are better suited for detailed, high-finish applications despite higher costs.

What Materials Are Used for Thermoforming Molds?

The material chosen for a thermoforming mold significantly impacts its performance, longevity, and cost. Selection depends on production volume, part complexity, and budget constraints.

Common mold materials include aluminum for durability, urethane for prototyping, and 3D-printed resins for rapid, complex designs.

-

Aluminum: Favored for high-volume runs due to its excellent thermal conductivity, ensuring uniform cooling and dimensional stability.

-

Urethane: A cost-effective choice for prototyping or short runs, offering decent wear resistance for limited cycles.

-

3D Printed Resins: Perfect for rapid prototyping and intricate geometries, especially in small-batch production.

Aluminum molds are the best choice for all thermoforming applications.False

Aluminum excels in durability and heat transfer for production runs, but urethane or 3D-printed molds are more economical for prototyping or low-volume needs.

What Are the Applications of Thermoforming Molds?

Thermoforming molds serve a broad spectrum of industries, leveraging their adaptability and efficiency to produce diverse products.

Thermoforming molds are integral in packaging, automotive, medical, and consumer goods, delivering lightweight, durable, and cost-effective solutions.

-

Packaging: Used for blister packs, clamshells, and food trays, capitalizing on scalability and affordability.

-

Automotive: Produces interior trim, dashboards, and light housings, requiring durability and aesthetic appeal.

-

Medical: Creates surgical trays and protective cases, prioritizing precision and sterility.

-

Consumer Goods: Shapes toys, appliance housings, and signage, benefiting from design flexibility and low tooling costs.

Thermoforming is only suitable for low-volume production.False

While ideal for prototyping due to low tooling costs, thermoforming also supports high-volume production, particularly for large, shallow parts like packaging trays.

How Does Thermoforming Compare to Other Technologies?

Thermoforming stands out against alternatives like injection molding, offering unique benefits and trade-offs depending on the project’s needs.

Thermoforming provides lower tooling costs5 and faster setup6 than injection molding, though it may lag in producing highly complex geometries.

| Technology | Tooling Cost | Setup Time | Part Complexity | Production Volume |

|---|---|---|---|---|

| Thermoforming | Low | Fast | Low to medium | Low to high |

| Injection Molding | High | Slow | High | High |

-

Pros of Thermoforming:

-

Lower tooling costs

-

Quicker setup times

-

Ideal for large parts and smaller volumes

-

Flexible material changes

-

-

Cons of Thermoforming:

-

Limited complexity in part design

-

Higher material waste from trimming

-

Potential for greater part variation

-

The decision between thermoforming and injection molding hinges on factors like production scale, design intricacy, and budget.

What Are the Key Steps in the Thermoforming Process?

The thermoforming process7 is a structured sequence of steps, each critical to producing high-quality parts.

Thermoforming involves heating a plastic sheet, shaping it with a mold, and finishing it through cooling and trimming, with precision in temperature and pressure being key.

-

Material Selection: Pick a thermoplastic sheet8 suited to the application’s needs.

-

Heating: Warm the sheet to its forming temperature until pliable.

-

Forming: Use vacuum, pressure, or mechanical force to mold the sheet.

-

Cooling: Let the part solidify in the mold.

-

Trimming: Remove excess material for the final shape.

-

Finishing: Add secondary processes like printing or assembly.

Precise control of heating temperature is crucial for successful thermoforming.True

Proper heating ensures the plastic is formable without degrading, preventing defects in the final product.

What Are the Common Materials Used in Thermoforming?

The choice of thermoplastic9 influences the thermoforming process and the part’s performance, with each material offering distinct properties.

Common thermoforming10 materials include ABS, PET, PVC, PP, PS, PC, and HDPE, selected for strength, clarity, or resistance.

| Material | Properties | Applications |

|---|---|---|

| ABS | Tough, impact-resistant | Automotive parts, consumer goods |

| PET | Clear, excellent barriers | Food packaging, blister packs |

| PVC | Flexible, chemical-resistant | Blister packs, medical devices |

| PP | Lightweight, fatigue-resistant | Food containers, appliances |

| PS | Rigid, brittle | Disposable cups, trays |

| PC | High impact, transparent | Safety glasses, medical devices |

| HDPE | Strong, moisture-resistant | Bottles, large parts |

What Are the Best Practices for Designing Thermoforming Molds?

Effective mold design11 enhances part quality and production efficiency, requiring attention to several key factors.

Mold design considerations include type, material, draft angles, radii, cooling, and tolerances for optimal performance.

-

Mold Type: Opt for male or female molds based on dimensional priorities.

-

Material: Use aluminum for production, urethane for prototypes, or 3D resins for complex designs.

-

Draft Angles: Incorporate at least a 2-degree angle on male molds for easy release.

-

Radii: Enlarge radii in deep-draw areas to avoid thinning.

-

Cooling Systems: Integrate efficient cooling for uniformity and speed.

-

Tolerances: Plan for precise tolerances to ensure accuracy.

Draft angles are only necessary for injection molding, not thermoforming.False

Draft angles are essential in thermoforming to facilitate part removal and prevent damage.

Conclusion

Thermoforming molds are vital to creating a wide array of products across industries, from packaging to medical devices. Understanding the types—vacuum, pressure, and mechanical—along with their applications and design considerations, empowers manufacturers to optimize their processes. Whether you’re producing cost-effective trays or detailed automotive components, thermoforming offers a flexible, efficient solution.

-

Explore this link to understand the various thermoforming molds and how they can enhance your manufacturing processes. ↩

-

Learn about vacuum forming's benefits and applications to see if it's the right choice for your production needs. ↩

-

Discover the unique advantages of pressure forming and how it can improve product quality in your projects. ↩

-

Discover the versatility of Mechanical Forming and its suitability for complex geometries and precise control in production. ↩

-

Understanding the significance of lower tooling costs can help businesses make informed manufacturing choices and optimize budgets. ↩

-

Discover how faster setup times can enhance production efficiency and reduce time-to-market for products. ↩

-

Understanding the thermoforming process is essential for anyone involved in manufacturing or design, as it impacts product quality and efficiency. ↩

-

Exploring the types of thermoplastic sheets can help you choose the right material for your specific application, enhancing product performance. ↩

-

Discover the various types of thermoplastics, their unique properties, and how they influence manufacturing processes. ↩

-

Explore this link to understand the thermoforming process, its benefits, and applications in various industries. ↩

-

Learn about effective mold design practices that enhance production efficiency and part quality in manufacturing. ↩