Vacuum forming is a versatile manufacturing process that transforms a flat plastic sheet into a three-dimensional shape by heating it and using a vacuum to mold it over a form. This technique is widely used for creating everything from packaging to automotive parts. However, the success of the final product hinges on one critical phase: preparing the plastic sheet. Proper preparation ensures the material is ready for heating and molding, delivering a high-quality finish that meets design specifications.

The plastic sheet for vacuum forming1 is prepared by selecting the appropriate thermoplastic2, cutting it to size, ensuring it’s clean, and securely clamping it in a frame for uniform heating.

This process may sound straightforward, but each step requires precision to avoid defects and optimize results. In this blog post, we’ll walk you through the preparation process3, explore material options, and highlight key considerations to help you master vacuum forming—whether you’re a beginner or a seasoned professional.

Vacuum forming is ideal for small to medium production runs due to its cost-effectiveness.True

Vacuum forming offers lower tooling costs and faster prototyping compared to methods like injection molding, making it a budget-friendly choice for smaller batches.

Vacuum forming can achieve the same level of detail as injection molding.False

While excellent for large, shallow parts, vacuum forming lacks the precision and fine detail of injection molding, especially for complex shapes.

What are the Key Steps in Preparing the Plastic Sheet for Vacuum Forming?

Preparing the plastic sheet is a multi-step process that sets the stage for successful vacuum forming. Each step addresses a specific need, from material compatibility to ensuring the sheet is ready to be shaped.

The plastic sheet is prepared by selecting the right thermoplastic, cutting it to size, ensuring it’s clean, and clamping it securely in a frame for heating. Let’s dive into these steps in detail.

1. Selecting the Material

The first step is choosing a thermoplastic that matches your project’s needs. Factors like strength, flexibility, heat resistance4, and cost come into play. Common materials include:

-

High Impact Polystyrene (HIPS)5: Affordable and easy to form, perfect for packaging and signage.

-

Acrylonitrile Butadiene Styrene (ABS)6: Durable and impact-resistant, ideal for automotive parts and enclosures.

-

Polyethylene (PE)7: Chemically resistant and lightweight, used for outdoor applications.

-

Polypropylene (PP)8: Heat-resistant and hygienic, great for food packaging.

-

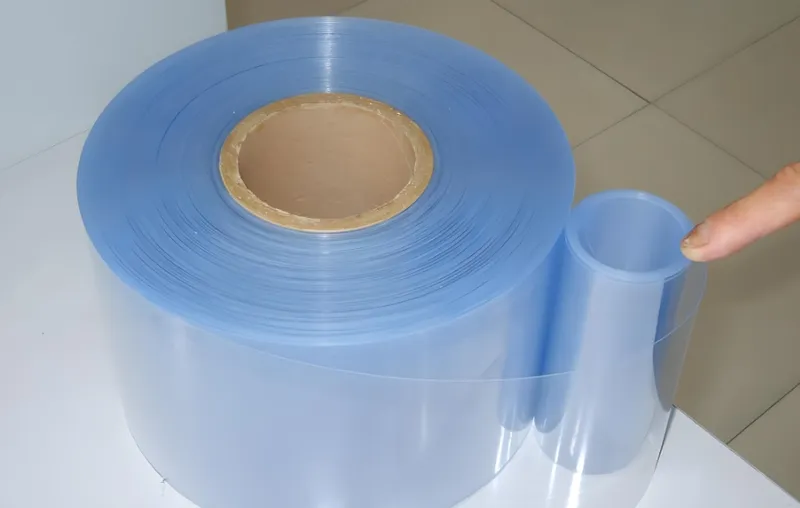

Polyvinyl Chloride (PVC)9: Flexible and versatile, commonly used in blister packaging.

Selecting the right material is critical—choose HIPS for cost savings on low-impact items, or opt for ABS when durability is a priority.

2. Cutting to Size

Next, the plastic sheet is cut to fit the mold and the clamping frame. This step ensures the sheet covers the mold completely without excessive overhang, minimizing waste and aligning with the part’s design. Precision here prevents issues like incomplete molding or excess material bunching up.

3. Ensuring Cleanliness

Before heating, the sheet must be spotless. Dust, oils, or debris can cause defects like bubbles or rough patches in the final product. A clean sheet is especially vital for applications requiring a polished finish, such as medical devices or consumer packaging.

4. Clamping for Heating

Finally, the sheet is clamped into a frame to hold it steady during heating. This ensures even heat distribution, making the plastic pliable for molding. For deeper parts, the sheet may be pre-stretched before the vacuum is applied, enhancing the shape’s depth and uniformity.

Material selection is the most critical step in vacuum forming preparation.True

The wrong material can lead to product failure or poor performance, making this choice foundational to success.

Pre-stretching the sheet is always necessary for vacuum forming.False

Pre-stretching is optional and typically used only for deeper parts to improve shape consistency.

What are the Common Materials Used in Vacuum Forming?

The material you choose defines the properties of your vacuum-formed product, from durability to cost. Here’s a closer look at the most popular options.

Common materials for vacuum forming include HIPS, ABS, PE, PP, and PVC, each offering unique properties like flexibility, strength, or heat resistance for various industries. Below is a table summarizing these materials, their applications, and typical heating times based on thickness.

| Material | Applications | Heating Time (1mm) | Heating Time (4mm) |

|---|---|---|---|

| HIPS | Packaging, signage | 30 seconds | 120 seconds |

| ABS | Automotive parts, enclosures | 40 seconds | 140 seconds |

| PE | Exterior parts, containers | 50 seconds | 200 seconds |

| PP | Food packaging, trays | 50 seconds | 200 seconds |

| PVC | Blister packaging | 30 seconds | 120 seconds |

High Impact Polystyrene (HIPS)

HIPS is a go-to for its low cost and ease of forming. It’s widely used in disposable items like trays and cups, though it’s less durable than alternatives.

Acrylonitrile Butadiene Styrene (ABS)

ABS offers superior strength, making it a favorite for parts that need to endure stress, such as car dashboards or equipment housings. It’s pricier but worth it for durability.

Polyethylene (PE)

PE excels in chemical resistance and flexibility, ideal for outdoor products like storage bins or playground equipment.

Polypropylene (PP)

PP’s heat resistance makes it a top choice for food-safe containers and medical trays, where sterilization is key.

Polyvinyl Chloride (PVC)

PVC’s flexibility suits it for packaging like blister packs, though it requires careful heating due to its lower heat tolerance.

HIPS is the most cost-effective material for all vacuum forming applications.False

While HIPS is budget-friendly, it’s not durable enough for high-impact or heat-intensive uses where ABS or PP shine.

Material thickness directly affects heating time in vacuum forming.True

Thicker sheets need more time to heat evenly, as shown in the table above.

What are the Challenges in Preparing the Plastic Sheet for Vacuum Forming?

Even with a clear process, challenges can arise that affect the outcome. Recognizing and addressing these issues is key to a smooth operation.

Common challenges include selecting the wrong material10, improper cutting11, contamination, and uneven heating, all of which can lead to defects or inefficiencies. Here’s what to watch out for:

1. Material Selection Errors

Picking a material that doesn’t match the application—like using HIPS for a high-stress part—can result in failure or unnecessary expense.

2. Inaccurate Cutting

A sheet cut too small won’t cover the mold, while one too large wastes material and risks wrinkles or uneven thickness.

3. Contamination

Impurities on the sheet can mar the finish, a serious issue in industries like healthcare or food packaging where cleanliness is non-negotiable.

4. Uneven Heating

Improper clamping or inconsistent heating can leave some areas too stiff or overly melted, causing thin spots or incomplete shapes.

Proper preparation can eliminate all defects in vacuum forming.False

Preparation is vital, but mold design and process settings also play a role in the final quality.

Vacuum forming is unsuitable for high-precision parts.True

Its strengths lie in large, shallow parts rather than intricate, high-precision components due to potential thickness variations.

Conclusion

Preparing a plastic sheet for vacuum forming is a meticulous process that lays the groundwork for a successful outcome. By selecting the right thermoplastic, cutting it accurately, keeping it clean, and clamping it securely, you can harness vacuum forming’s advantages—cost-effectiveness, speed, and versatility—for projects ranging from prototypes to production runs.

Understanding these steps empowers you to avoid common pitfalls and tailor the process to your needs.

With the right preparation, vacuum forming can deliver high-quality results efficiently and economically, making it a valuable tool in modern manufacturing.

-

Gain a deeper understanding of vacuum forming and its applications in various industries by exploring this informative resource. ↩

-

Understanding thermoplastics is crucial for successful vacuum forming. Explore this link to learn about the best options available. ↩

-

Mastering the preparation process is key to achieving high-quality vacuum formed products. Discover expert tips and techniques here. ↩

-

Learning about heat resistance can guide you in selecting materials that withstand the forming process, enhancing product performance. ↩

-

Exploring the benefits of HIPS can guide you in selecting cost-effective materials for your projects, especially in packaging. ↩

-

Learning about ABS's durability and applications can help you make informed decisions for automotive and enclosure projects. ↩

-

Explore the advantages of Polyethylene (PE) for outdoor use, including its chemical resistance and lightweight properties, to make informed choices. ↩

-

Learn why Polypropylene (PP) is a top choice for food packaging due to its heat resistance and hygienic qualities, ensuring safety and quality. ↩

-

Discover the versatility of Polyvinyl Chloride (PVC) in packaging applications, particularly in blister packaging, to enhance your product designs. ↩

-

Learn about the critical impact of material selection on manufacturing outcomes to avoid costly mistakes. ↩

-

Discover how cutting accuracy influences product quality and efficiency in manufacturing processes. ↩