Choosing the right extruder for your manufacturing needs can feel overwhelming given the variety of options available. Whether you're crafting plastic pipes, metal profiles, or food products, the extruder you select plays a pivotal role in ensuring high-quality outcomes and operational efficiency. In this detailed guide, we’ll walk you through the essential factors to consider, compare different extruder types1, and offer practical advice to help you make a well-informed choice.

Selecting the right extruder hinges on your specific material, product shape, production rate, budget, and space constraints, with single-screw extruder2s ideal for simple materials and twin-screw excelling in complex mixing tasks.

Understanding extruders and their applications can unlock significant advantages for your industry. Let’s dive into how material properties, product specifications, and production goals shape your extruder decision.

Single-screw extruders are more cost-effective for simple materials.True

Their straightforward design and lower cost make them perfect for processing uniform materials like plastics and rubber.

Twin-screw extruders are essential for all extrusion tasks.False

While they excel at mixing, twin-screw extruders aren’t always needed for simple materials and can increase costs unnecessarily.

What are the Common Types of Extruders?

Extruders are vital tools in industries that demand continuous production of shaped materials, boosting efficiency and cutting costs.

Common extruder types include single-screw and twin-screw, each tailored to specific materials and applications across plastics, metals, food, and rubber sectors.

| Extruder Type | Recommended Materials | Notes |

|---|---|---|

| Single-Screw | Homogeneous materials | Simpler, cost-effective |

| Twin-Screw | Complex materials | Superior mixing, higher cost |

Single-Screw Extruder

The single-screw extruder is the most basic and widely used type, featuring a single rotating screw within a barrel that conveys, melts, and shapes material. It’s perfect for homogeneous materials like plastics and rubber, commonly applied in producing pipes and profiles.

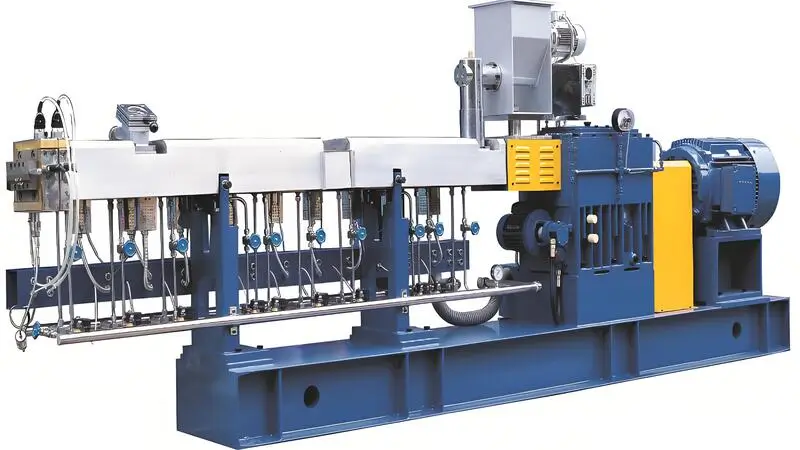

Twin-Screw Extruder

Twin-screw extruders boast two intermeshing screws, offering enhanced mixing capabilities. They’re ideal for complex materials needing thorough blending, such as composites, food products, and pharmaceuticals, and come in co-rotating or counter-rotating variants.

Other Types

Specialized extruders like split twin-screw, two-stage, vented, reciprocating single-screw pin-barrel, and planetary roller extruders cater to niche applications, providing tailored solutions for specific materials or production needs.

Each type serves distinct purposes, making it critical to align your choice with your material and production goals.

Single-screw extruders excel with simple, uniform materials.True

Their design optimizes processing for materials that don’t need extensive mixing, balancing efficiency and cost.

Twin-screw extruders are limited to plastics.False

Their versatility extends beyond plastics to food processing, pharmaceuticals, and more due to their mixing prowess.

What are the Steps in the Extrusion Process?

The extrusion process is key to creating consistent, continuous products across various industries by shaping materials through a die.

The extrusion process3 includes feeding, conveying, melting, mixing, pressurizing, shaping, cooling, and cutting or coiling, widely used in plastics, metals, food, and rubber for its efficiency.

Feeding

Raw material—pellets, powder, or granules—is fed into the extruder’s hopper, with the feed rate controlled for steady flow.

Conveying

The screw rotates, moving material through the barrel. Screw speed and barrel temperature influence this stage.

Melting (for Thermoplastics)

For thermoplastics4, heaters and friction melt the material, with temperature zones tailored to its properties.

Mixing

The screw ensures material uniformity, enhanced in twin-screw models5 by additional mixing elements.

Pressurizing

Pressure builds, pushing material through the die, adjusted to match material and product needs.

Shaping

The material exits the die, taking on its final cross-sectional shape.

Cooling

The product cools—via water baths or air—to solidify its form.

Cutting or Coiling

The finished product is cut to length or coiled, depending on its intended use.

Extrusion always yields uniform products.False

Uniformity varies with material consistency, screw design, and process control.

Extrusion speeds up continuous production.True

Its continuous nature reduces downtime, boosting efficiency.

What are the Key Factors in Choosing an Extruder?

Picking the right extruder is crucial for optimizing production and product quality.

Key factors include material type6, product shape, production rate7, budget, and space, guiding you to the best extruder for your needs.

Material Type

What are you processing—plastics, metals, food, or rubber? Single-screw extruders suit plastics, while twin-screw models handle food blends.

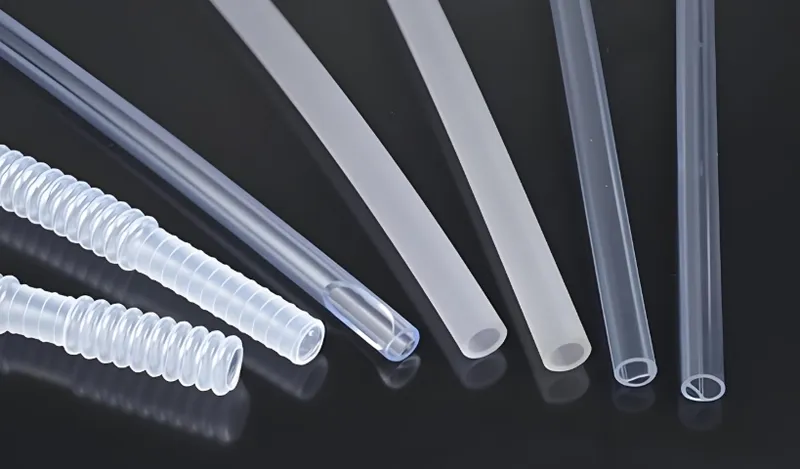

Product Shape

The final product’s shape—pipes, profiles, sheets, or films—dictates die design and extruder setup.

Production Rate

Your output needs (e.g., kg/hr or m/min) determine extruder size and power, with high volumes requiring robust machines.

Budget

Balance initial costs with ongoing expenses. Single-screw extruders are cheaper upfront than twin-screw options.

Space Constraints

Consider the footprint of the extruder8 and its auxiliary equipment like cooling or cutting systems.

Regulatory Requirements

Ensure compliance with industry standards, especially in food or pharmaceutical applications.

Material type is the top factor in extruder choice.True

Different materials demand specific extruder designs for effective processing.

Any extruder fits all production rates.False

Extruders are sized for specific outputs; larger rates need bigger machines.

What are the Applications of Extruders?

Extruders provide versatile manufacturing solutions, enabling efficient production across multiple industries.

Extruders are employed in plastics, metals, food, rubber, and 3D printing for continuous shaping, enhancing efficiency and reducing costs.

Plastics Industry

Extruders craft pipes, profiles, sheets, and films for construction, packaging, and automotive uses, often with single-screw models.

Metals Industry

Hot extrusion shapes aluminum profiles for windows, doors, and structural components using specialized extruders.

Rubber Industry

Extruders form tires, seals, and hoses, requiring precise temperature control to avoid premature curing.

Food Industry

Twin-screw extruders produce snacks, cereals, pasta, and pet food, ensuring uniform texture and quality.

3D Printing

Desktop extruders create prototypes and small-scale items, typically with materials like TPU.

Extruders cut material waste.True

Precise control in continuous production minimizes waste.

Extruders are plastics-only tools.False

They span metals, food, rubber, and more, showcasing their adaptability.

What are the Differences Between Single-Screw and Twin-Screw Extruders?

Knowing the distinctions between single-screw and twin-screw extruders is vital for your decision.

Single-screw extruders are simpler and cheaper for uniform materials, while twin-screw extruders offer advanced mixing for complex ones.

| Feature | Single-Screw Extruder | Twin-Screw Extruder |

|---|---|---|

| Material Compatibility | Homogeneous materials | Complex materials |

| Mixing Capability | Limited | Excellent |

| Cost | Lower | Higher |

| Complexity | Simpler design | More complex |

| Applications | Plastics, rubber | Composites, food |

Design and Operation

Single-screw extruders use one screw, making them straightforward. Twin-screw extruders, with two screws, enhance material control and mixing.

Material Compatibility

Single-screw excels with uniform materials; twin-screw tackles blends needing thorough mixing.

Cost and Complexity

Single-screw models are budget-friendly and low-maintenance, while twin-screw options are pricier and more intricate.

Applications

Single-screw suits basic plastic extrusion; twin-screw shines in food and pharmaceutical mixing tasks.

Conclusion

Choosing the right extruder means weighing your material, product shape, production rate, budget, and space constraints. Single-screw extruders are great for simple, uniform materials, while twin-screw models handle complex mixing needs. By grasping these options and their uses, you can optimize your manufacturing process effectively.

-

Discover the various extruder types and their specific applications to make an informed choice for your manufacturing needs. ↩

-

Explore the benefits of single-screw extruders to understand their efficiency and cost-effectiveness for your production needs. ↩

-

Understanding the extrusion process can enhance your knowledge of manufacturing techniques across various industries. ↩

-

Exploring thermoplastics will provide insights into their properties and significance in the extrusion process. ↩

-

Learning about twin-screw models can reveal their benefits in achieving material uniformity during extrusion. ↩

-

Learning about material compatibility with extruders is essential for achieving the best product quality. ↩

-

Exploring this topic will provide insights into optimizing your production efficiency and equipment choice. ↩

-

Understanding the various types of extruders can help you make an informed decision for your production needs. ↩