Servo-Driven Extruder Systems are transforming the manufacturing landscape by delivering precise control, flexibility, and efficiency in the extrusion process. These advanced systems utilize servomotors to manage the extrusion of materials such as plastics and metals, ensuring high-quality output for industries that prioritize accuracy and consistency.

Servo-Driven Extruder Systems leverage servomotors for precise extrusion control, enhancing quality, flexibility, and efficiency across industries like aerospace, 3D printing, and medical manufacturing.

Understanding the advantages of Servo-Driven Extruder Systems can empower manufacturers to optimize their production processes. This blog post explores their key benefits, compares them with other technologies, and highlights their diverse applications.

Servo-Driven Extruder Systems offer higher precision than traditional systems.True

Servomotors provide exact control over speed and torque, ensuring uniform product dimensions.

Servo-Driven Extruder Systems are more expensive to maintain than hydraulic systems.False

They require less maintenance due to the absence of fluid leaks and fewer moving parts.

What Are Servo-Driven Extruder Systems?

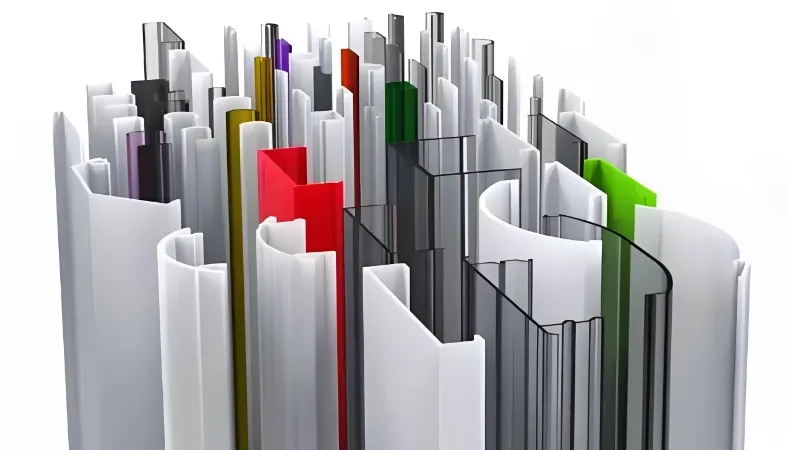

Servo-Driven Extruder Systems are cutting-edge machines that employ servomotors to achieve unparalleled precision in the extrusion process. Extrusion is a manufacturing technique where materials are shaped by being forced through a die, creating objects with a consistent cross-sectional profile. According to Servomotor - Wikipedia1, servomotors are actuators that enable precise control of position, velocity, and acceleration, making them ideal for high-accuracy applications.

These systems are often called "servo extruders" or "precision extruders" and are categorized by:

-

Process: Continuous or batch extrusion.

-

Materials: Plastics, metals, food products, etc.

-

Applications: Aerospace, medical devices, 3D printing, and beyond.

The hallmark of Servo-Driven Extruder Systems is their closed-loop control, which uses feedback mechanisms like encoders to make real-time adjustments, ensuring consistent quality throughout production.

What Are the Benefits of Servo-Driven Extruder Systems?

Servo-Driven Extruder Systems outperform traditional extrusion technologies in several key areas, making them a top choice for precision manufacturing.

Precision and Quality

Servo-Driven Extruder Systems excel in delivering exceptional precision and maintaining high-quality standards. The servomotors’ ability to finely tune speed and torque ensures uniform product dimensions. This is critical in industries like medical device manufacturing, where deviations can compromise functionality. As noted in How Servo Extruders Are Changing the Game - Divbyz2, this precision is vital for producing complex parts with tight tolerances.

Flexibility and Versatility

These systems are highly adaptable, capable of processing a wide range of materials and conditions. From adjusting to varying viscosities in plastics to handling the high torque needed for metals, Servo-Driven Extruder Systems can be customized to meet specific needs. This versatility suits applications ranging from 3D printing intricate prototypes to producing large-scale construction components.

Efficiency and Maintenance

Compared to hydraulic or pneumatic systems, Servo-Driven Extruder Systems are more energy-efficient and require less maintenance. Hydraulic systems often face issues like fluid leaks and demand frequent upkeep, while servo-driven systems minimize downtime. Their precise control also reduces material waste, boosting overall efficiency.

Integration with Automation

A standout feature is their seamless integration with automated manufacturing lines. Connected to digital control interfaces, these systems allow remote monitoring and adjustments, enhancing productivity. This aligns with Industry 4.0 practices, such as predictive maintenance, as highlighted in Servo-driven devices expand machine capabilities | Control Design3.

Servo-Driven Extruder Systems reduce operational costs over time.True

Their energy efficiency and low maintenance needs lead to significant cost savings in the long run.

Servo-Driven Extruder Systems are only suitable for small-scale production.False

These systems are scalable and can be used in both small and large-scale manufacturing environments.

How Do Servo-Driven Extruder Systems Compare to Other Technologies?

Servo-Driven Extruder Systems stand out when compared to alternatives like stepper-driven and hydraulic systems. The table below outlines their differences:

| Feature | Servo-Driven Extruder | Stepper-Driven Extruder | Hydraulic System |

|---|---|---|---|

| Precision | High (micron-level) | Moderate | Low to Moderate |

| Maintenance | Low | Moderate | High (fluid leaks) |

| Energy Efficiency | High | Moderate | Low |

| Cost (Initial) | High | Low | Moderate to High |

| Flexibility | High | Moderate | Low |

Derived from insights in 15 Things to Know About Servo-Driven Injection Machines | Plastics Technology4, this comparison underscores the superior precision, reduced maintenance, and energy efficiency of Servo-Driven Extruder Systems, despite their higher upfront cost.

What Are the Applications of Servo-Driven Extruder Systems?

Servo-Driven Extruder Systems are indispensable in industries requiring precision and reliability.

Servo-Driven Extruder Systems shine in aerospace, 3D printing, and medical manufacturing, producing high-precision components with consistent quality.

Aerospace

In aerospace, these systems craft complex parts with tight tolerances, ensuring safety and performance in critical applications.

3D Printing

For 3D printing, they provide precise material flow control, enabling high-quality prototypes and end-use products, as detailed in 3D Printers Evolution: The Advantage Of Servo Systems - Motion Control Blog5.

Medical Manufacturing

Medical manufacturing relies on their ability to produce consistent, accurate components like catheters and implants, where precision is non-negotiable.

Beyond these, Servo-Driven Extruder Systems are used in consumer goods, automotive parts, and construction materials, showcasing their broad applicability.

Servo-Driven Extruder Systems are crucial for high-precision industries.True

Their ability to maintain tight tolerances makes them indispensable in sectors like aerospace and medical manufacturing.

Servo-Driven Extruder Systems cannot handle large-scale production.False

These systems are scalable and can be adapted for both small and large-scale manufacturing.

How Do Servo-Driven Extruder Systems Work?

The operation of a Servo-Driven Extruder System involves a series of steps ensuring precision and quality.

The Servo-Driven Extruder System process includes material feeding, melting, extrusion with servomotor control, shaping, and cooling, delivering precision and consistency.

-

Material Feeding: Raw material enters the extruder via a hopper.

-

Melting/Heating: The material is heated to a molten state, tailored to its properties.

-

Extrusion: The servomotor drives the screw or plunger, pushing material through the die with precise speed and torque.

-

Shaping: The die molds the material into the desired cross-section.

-

Cooling/Curing: The extruded product is cooled or cured to solidify its shape.

This process, outlined in Extruders - an overview | ScienceDirect Topics6, emphasizes the servomotor’s role in achieving uniform extrusion.

Conclusion

Servo-Driven Extruder Systems mark a leap forward in extrusion technology, offering unmatched precision, flexibility, and efficiency. Though they require a higher initial investment, their long-term advantages—lower maintenance, energy savings, and superior product quality—make them a smart choice for manufacturers. As industries advance toward automation and precision manufacturing, these systems are set to drive the future of production.

For further insights, explore resources like Servomotor - Wikipedia or industry blogs on servo technology applications.