Electric-powered extruders are transforming the manufacturing landscape, particularly in industries like plastics, where efficiency, precision, and sustainability are critical. These machines, driven by electric motors, are increasingly favored for their ability to reduce energy consumption, enhance control over production processes, and align with environmental goals. As manufacturers seek innovative solutions to lower costs and improve product quality, electric-powered extruders1 stand out as a game-changer.

Electric-powered extruders are gaining popularity for their energy efficiency, precision control2, and environmental benefits, making them a preferred choice in industries like plastics manufacturing for sustainable and cost-effective production.

This article explores the reasons behind their rising adoption, delving into their definitions, applications, technical advantages, practical considerations, and their role within the broader manufacturing ecosystem. By understanding these facets, manufacturers can harness the potential of electric-powered extruders to optimize their operations.

Electric-powered extruders are more energy-efficient than traditional hydraulic extruders.True

Electric extruders consume less energy due to direct drive systems, reducing operational costs and environmental impact.

Electric-powered extruders are only suitable for small-scale production.False

While they excel in precision, electric extruders are also used in large-scale manufacturing due to their efficiency and scalability.

- 1. What is an Electric-Powered Extruder?

- 2. What are the Typical Applications of Electric-Powered Extruders?

- 3. How Do Electric-Powered Extruders Compare to Other Technologies?

- 4. What is the Process Workflow for Electric-Powered Extruders?

- 5. What are the Practical Considerations for Selecting an Electric-Powered Extruder?

- 6. How Do Electric-Powered Extruders Fit into the Broader Manufacturing Ecosystem?

- 7. Conclusion

What is an Electric-Powered Extruder?

Electric-powered extruders are advanced machines that utilize electric motors to drive the extrusion process, shaping materials such as plastics, metals, or food products by forcing them through a die. Unlike hydraulic or pneumatic systems, which depend on fluid or air pressure, electric extruders provide direct and precise control over extrusion speed and temperature, resulting in consistent, high-quality outputs.

Electric-powered extruders use electric motors for precise control in shaping materials like plastics, offering energy efficiency3 and consistent quality in manufacturing processes.

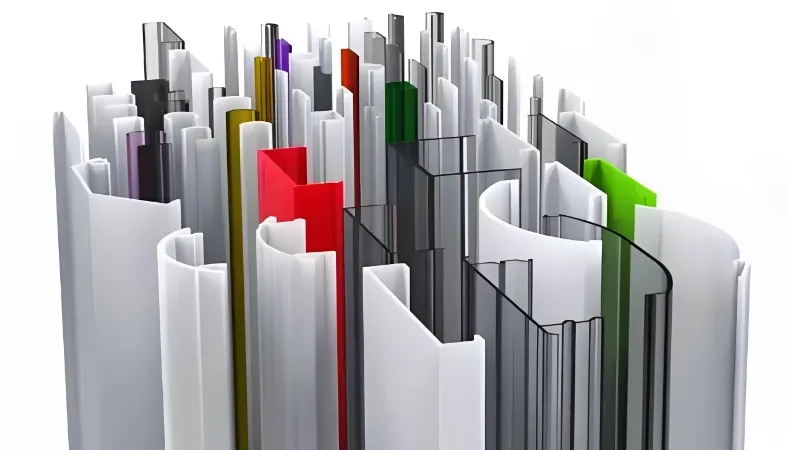

These extruders can be classified based on several criteria:

-

By Type of Extruder:

- Single-screw extruder

- Twin-screw extruder

- Ram extruder

- Planetary roller extruder

-

By Material Handled:

- Plastics

- Metals

- Food

- Ceramics

- Rubber

-

By Application Industry:

- Plastics manufacturing4

- Metalworking

- Food processing

- Ceramics

- Rubber production

This versatility allows manufacturers to select the most suitable electric-powered extruder for their specific needs, capitalizing on the technology’s precision and efficiency.

Electric-powered extruders are only used in plastics manufacturing.False

While prevalent in plastics, they are also utilized in food processing, metalworking, and other industries.

What are the Typical Applications of Electric-Powered Extruders?

Electric-powered extruders are integral to industries requiring precise and efficient material shaping. Their ability to deliver uniform quality makes them indispensable in applications where consistency is paramount.

Electric-powered extruders are commonly used in plastics manufacturing for products like pipes, films, and profiles, as well as in food processing for items like pasta and snacks.

In plastics manufacturing, they excel at producing:

-

Plastic pipes and tubing

-

Films for packaging

-

Profiles for construction and automotive parts

-

Medical device components

-

Food packaging materials

Beyond plastics, their precision supports:

-

Food processing (e.g., pasta, cereal, and snack production)

-

Metal extrusion for lightweight components

-

Rubber production for seals and gaskets

Electric-powered extruders are ideal for high-precision applications.True

Their precise control over speed and temperature ensures consistent product quality, especially in industries like medical devices and food packaging.

How Do Electric-Powered Extruders Compare to Other Technologies?

When pitted against hydraulic and pneumatic extruders, electric-powered extruders offer distinct advantages, though they may involve higher initial investments.

Electric-powered extruders are more energy-efficient and offer better precision than hydraulic and pneumatic extruders, but may have higher upfront costs.

| Aspect | Electric-Powered Extruders | Hydraulic Extruders | Pneumatic Extruders |

|---|---|---|---|

| Energy Efficiency5 | High, with lower operating costs | Lower, due to energy losses in fluid systems | Moderate, depends on air compressor efficiency |

| Precision Control | Excellent, with digital controls for speed/temperature | Good, but less precise due to fluid dynamics | Limited, less consistent control |

| Maintenance | Low, fewer components, no oil leaks | Higher, risk of leaks and fluid contamination | Moderate, requires air system maintenance |

| Environmental Impact | Cleaner, quieter, aligns with sustainability goals | Potential oil leaks, noisier | No oil, but noise from compressors |

| Initial Cost | Potentially higher | Lower initial cost | Varies, often moderate |

This comparison highlights that, despite a potentially higher initial cost, electric-powered extruders deliver long-term savings through reduced energy use, lower maintenance, and a smaller environmental footprint.

Electric-powered extruders have lower maintenance costs than hydraulic extruders.True

With fewer moving parts and no hydraulic fluids, electric extruders require less frequent maintenance.

What is the Process Workflow for Electric-Powered Extruders?

The extrusion process in electric-powered extruders follows a series of precise steps, each optimized for quality and efficiency.

The extrusion process includes feeding, melting, mixing, pressurizing, shaping, cooling, and cutting, with precise control over each stage for optimal results.

-

Feeding: Raw materials, such as plastic pellets, are introduced into the extruder’s hopper.

-

Melting/Plasticizing: The material is heated and melted by the rotating screw and external heaters.

-

Mixing: Additives or colorants are blended into the molten material.

-

Pressurizing: The screw builds pressure to push the melt through the die.

-

Shaping: The material is extruded through a die to form the desired shape.

-

Cooling: The extruded product is cooled to solidify and retain its shape.

-

Cutting/Collecting: The product is cut to length or collected for further processing.

Material compatibility plays a vital role:

-

Melting Temperature: Varies by material (e.g., polypropylene requires higher temperatures than polyethylene).

-

Viscosity: High-viscosity materials like PVC demand greater pressure.

-

Thermal Stability: Heat-sensitive materials need careful temperature management to avoid degradation.

Material selection significantly impacts the extrusion process.True

Different materials have unique properties that affect temperature, pressure, and processing requirements.

What are the Practical Considerations for Selecting an Electric-Powered Extruder?

Selecting the right extruder requires balancing production needs with operational constraints.

Key considerations include material type, product specifications, production rate, energy efficiency, and maintenance requirements.

A practical design checklist includes:

| Checklist Item | Description |

|---|---|

| Material Type | Ensure compatibility with extruder capabilities |

| Product Shape and Size | Determine appropriate die design |

| Required Production Rate | Match extruder capacity to output needs |

| Power Source | Prefer electric for efficiency and control |

| Extruder Type | Choose single-screw or twin-screw based on material |

| Temperature Control Requirements | Ensure precise temperature management |

| Additive Handling | Check compatibility with additives or fillers |

| Energy Efficiency | Opt for models with high energy efficiency |

| Maintenance Requirements | Look for low-maintenance designs |

| Cost of Ownership | Balance initial costs with long-term savings |

For decision-making:

-

Precision Needs: Electric extruders shine in applications requiring tight tolerances.

-

Material Sensitivity: Precise temperature control benefits heat-sensitive materials.

-

Production Volume: They suit both small and large-scale production due to their scalability.

Electric-powered extruders are suitable for both small and large-scale production.True

Their scalability and efficiency make them adaptable to various production volumes.

How Do Electric-Powered Extruders Fit into the Broader Manufacturing Ecosystem?

Electric-powered extruders are not standalone solutions; they integrate seamlessly into a wider manufacturing network.

Electric-powered extruders connect with upstream processes like material preparation and downstream processes like cutting and assembly, enhancing overall manufacturing efficiency.

-

Upstream Technologies: Include plastic pelletizing, compounding, and blending to prepare materials.

-

Downstream Technologies: Encompass cutting, shaping, printing, or assembly to finalize products.

-

Alternative Forming Processes: Such as injection molding or blow molding, provide complementary shaping methods.

This interconnectedness allows manufacturers to streamline their production lines, leveraging electric-powered extruders6 for maximum efficiency.

Electric-powered extruders can be integrated with other manufacturing technologies for streamlined production.True

Their compatibility with upstream and downstream processes enhances overall workflow efficiency.

Conclusion

Electric-powered extruders are surging in popularity due to their energy efficiency, precision control, environmental advantages, and reduced maintenance costs. As industries like plastics manufacturing prioritize sustainability and cost-effectiveness, these machines offer a robust solution. By exploring their applications, technical processes, and practical benefits, manufacturers can make informed decisions to elevate their production capabilities.

-

Explore how electric-powered extruders enhance efficiency and sustainability in manufacturing processes, making them a game-changer. ↩

-

Discover the significance of precision control in manufacturing and how it leads to higher quality outputs with electric-powered extruders. ↩

-

Learn about the energy-saving advantages of electric-powered extruders and their impact on production costs and sustainability. ↩

-

Discover how advancements in technology are transforming plastics manufacturing, enhancing efficiency and product quality. ↩

-

Learn about the energy efficiency of electric-powered extruders and how they contribute to cost savings and sustainability in production. ↩

-

Explore the advantages of electric-powered extruders to enhance your manufacturing efficiency and production quality. ↩