Energy-efficient extruders are revolutionizing manufacturing by slashing energy consumption while boosting product quality and production efficiency. These innovative machines are making waves in industries like plastics and food processing, where energy costs are a major hurdle. By integrating cutting-edge technologies such as variable speed drives, high-efficiency motors1, and optimized screw designs, energy-efficient extruders can cut energy use by up to 30-50%, according to insights from The Top Energy Efficiency Tips for Reducing Plastic Extrusion Energy Costs. This not only trims production costs but also aligns with sustainability goals by shrinking carbon footprints. With the global extruders market projected to hit USD 14.9 billion by 2032, driven by demand for energy-efficient solutions per Extruders Market Size Share Scope Industry Trends 2032, grasping their impact is vital for industry pros and decision-makers.

Energy-efficient extruders slash energy use by up to 50%, transforming industries like plastics and food processing with cost savings and sustainability benefits.

This guide dives into the essentials of energy-efficient extruders2, their applications, technical details, practical tools for implementation, and their place in the wider industrial ecosystem. Whether you’re aiming to cut costs, meet green targets, or stay competitive, this article equips you with the know-how to harness these game-changing machines.

Energy-efficient extruders can reduce energy consumption by up to 50%.True

Technologies like variable speed drives and high-efficiency motors optimize energy use, delivering substantial savings.

Energy-efficient extruders are only useful for large-scale operations.False

Small and medium-sized businesses can also reap cost and sustainability benefits, making them versatile across scales.

- 1. What Are Energy-Efficient Extruders and How Do They Work?

- 2. How Do Energy-Efficient Extruders Benefit Different Industries?

- 3. What Are the Key Technical Aspects of Energy-Efficient Extruders?

- 4. How Can You Implement Energy-Efficient Extruders Effectively?

- 5. How Do Energy-Efficient Extruders Fit into the Broader Industrial Ecosystem?

- 6. Conclusion

What Are Energy-Efficient Extruders and How Do They Work?

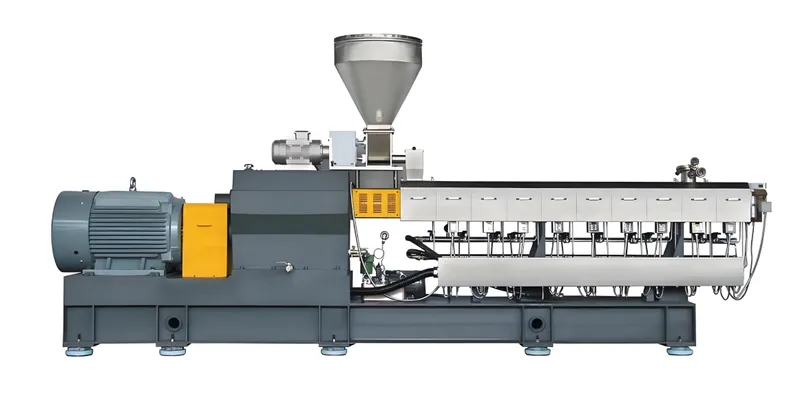

Energy-efficient extruders are advanced machines designed to minimize energy use during extrusion while maintaining or enhancing output quality, making them indispensable in sectors like plastics and food processing.

Energy-efficient extruders leverage high-efficiency motors and optimized screw designs to cut energy use by up to 50%, boosting sustainability and reducing costs.

| Extruder Type | Energy Savings Potential | Key Technologies |

|---|---|---|

| Single-Screw | Up to 30% | High-efficiency motors |

| Twin-Screw | Up to 50% | Variable speed drives |

Definition and Core Principles

Energy-efficient extruders are built to reduce energy consumption through technologies like variable speed drives3, high-efficiency motors4, and optimized screw designs. Their core principle is to minimize energy loss by fine-tuning motor performance, precisely controlling process parameters, and operating at optimal speeds and temperatures. For example, The Top Energy Efficiency Tips for Reducing Plastic Extrusion Energy Costs notes that these advancements can significantly lower energy use in plastic extrusion.

Classification of Energy-Efficient Extruders

-

By Process: Single-screw extruders excel in simpler plastic applications, while twin-screw models offer flexibility and mixing efficiency for food processing, as detailed in Food Extrusion - an overview.

-

By Materials: In plastics, they process polymers like PVC, HDPE, and PET. In food, they handle high-starch products like pasta and cereals, with material-specific conditions being key.

-

By Applications: They produce pipes, profiles, and sheets in plastics Plastic Extruders for Energy-Efficient Production and snacks, cereals, and pet food in food processing Applications of food extrusion technology.

Energy-efficient extruders are limited to plastics manufacturing.False

They’re also critical in food processing, producing items like snacks and cereals with enhanced efficiency.

These extruders require less maintenance than traditional models.True

Optimized designs reduce wear, cutting maintenance needs.

How Do Energy-Efficient Extruders Benefit Different Industries?

Energy-efficient extruders deliver major advantages by slashing energy costs and boosting sustainability, making them a smart pick for industries looking to streamline operations.

Energy-efficient extruders cut energy costs by up to 50% and improve sustainability in industries like plastics and food processing, enhancing product quality.

Typical Application Scenarios

These extruders shine where energy costs loom large. In plastics, they’re ideal for producing pipes, profiles, and sheets, especially in cost-conscious facilities. In food processing, they streamline snack, cereal, and pasta production, as highlighted in How Extrusion Shapes Food Processing.

Suggestions Based on Industry and Product Needs

Industries with high energy use or sustainability goals—like plastics manufacturers in energy-intensive regions or food producers targeting eco-conscious consumers—should prioritize these extruders. They’re also perfect for products needing precise temperature control, per Sustainable Energy Production in the Food Industry.

Pros and Cons Compared to Other Technologies

-

Pros: Up to 50% energy savings via variable speed drives How variable speed drives save energy for manufacturers, better product quality through precise control, and lower carbon footprints.

-

Cons: Higher upfront costs can deter smaller firms, and they may need specialized training or struggle with niche materials.

Energy-efficient extruders are cost-effective for every business.False

High initial costs can be a hurdle for smaller firms despite long-term savings.

They improve product quality alongside energy savings.True

Precise parameter control ensures consistent, high-quality outputs.

What Are the Key Technical Aspects of Energy-Efficient Extruders?

Mastering the technical details of energy-efficient extruders5 is essential for maximizing their benefits, as they hinge on specific processes and material considerations.

Energy-efficient extruders optimize energy through advanced motors, precise temperature control, and material-specific processing for efficiency and quality.

Process Workflow Breakdown

-

Plastics: Pellets feed into a hopper, melt and mix in the barrel, and exit through a die Investigation of the process energy demand in polymer extrusion.

-

Food: Ingredients mix, cook under heat and shear, form, and cut to size Food Extrusion Process.

Material Compatibility

- Plastics: PVC and HDPE need tailored settings due to varying melting points.

- Food: Pasta requires low temps and moisture, while meat analogues need high shear Food extrusion - Wikipedia.

Key Steps and Parameters

-

Temperature Control: Prevents overheating and ensures material integrity.

-

Screw Speed: Balances energy use and material flow Energy Consumption Analysis for a Single Screw Extruder.

-

Die Pressure: Shapes the final product.

All materials use the same extruder settings for efficiency.False

Materials demand specific settings for optimal energy use and quality.

Screw speed control is key to energy efficiency.True

It reduces consumption and enhances material flow.

How Can You Implement Energy-Efficient Extruders Effectively?

Successful adoption requires strategic planning and the right tools to maximize benefits.

Effective implementation hinges on sizing, motor selection, and temperature control6, guided by checklists and decision-making tools.

Design Checklist

-

Sizing: Match extruder size to production rate.

-

Motor Matching: Use high-efficiency motors for up to 30% savings Energy Efficiency - Solutions - Extruder.

-

Temperature Systems: Ensure precise control for stability.

Process Selection Decision-Making

| Decision Factor | Consideration | Action |

|---|---|---|

| High energy costs | Significant expense | Prioritize efficient models |

| Budget constraints | Limited funds | Consider retrofits |

| Sustainability goals | Environmental standards | Opt for efficient extruders |

They’re always the best choice for any production line.False

They excel where energy costs and sustainability matter most.

Retrofits can boost traditional extruder efficiency.True

Upgrades like new motors enhance performance cost-effectively.

How Do Energy-Efficient Extruders Fit into the Broader Industrial Ecosystem?

These extruders are linchpins in the industrial landscape, linking with related technologies to drive efficiency and sustainability.

Energy-efficient extruders connect with material synthesis, finishing, and control systems, fostering innovation across the supply chain.

Related Technologies

-

Upstream: Polymer production or ingredient mixing Energy efficiency in extrusion-related polymer processing7.

-

Downstream: Cutting, packaging, or assembly Extrusion Efficiency: The Key to Reducing Energy Costs.

-

Related: Pelletizers, die designs, and advanced controls Modernization8: Ways to Increase Energy Efficiency in Extrusion.

They operate independently of other tech.False

They integrate with upstream and downstream processes for system-wide efficiency.

Advanced controls maximize their benefits.True

Precision enhances savings and quality.

Conclusion

Energy-efficient extruders are reshaping industries by cutting energy use by up to 50%, reducing costs, and advancing sustainability. Vital in plastics and food processing, they’re poised to drive the extruders market to USD 14.9 billion by 2032. By mastering their technicalities, implementation, and ecosystem role, businesses can unlock their full potential for long-term success.

-

Learn about the role of high-efficiency motors in cutting energy consumption and improving production efficiency. ↩

-

Explore how energy-efficient extruders are transforming manufacturing by reducing costs and enhancing sustainability. ↩

-

Discover how variable speed drives optimize machinery performance and lead to significant energy savings in various industries. ↩

-

Learn about the role of high-efficiency motors in reducing energy consumption and improving operational efficiency. ↩

-

Explore how energy-efficient extruders can significantly reduce energy costs and enhance sustainability in various industries. ↩

-

Discover the critical role of temperature control in ensuring product quality and efficiency in extrusion processes across industries. ↩

-

Explore this resource to discover innovative practices that can significantly enhance energy efficiency in polymer processing, leading to cost savings and sustainability. ↩

-

This link will provide insights into cutting-edge control technologies that can modernize extrusion processes, enhancing efficiency and productivity. ↩