Biocompatible plastics are essential in the medical industry, particularly for extrusion processes that create critical components like IV tubing and catheters. These materials must be safe for contact with living tissues, offering flexibility, transparency, and compatibility with bodily fluids. Common choices include polyvinyl chloride (PVC), polyurethane (PU), and silicone, each with unique properties and applications.

Medical extrusion uses biocompatible plastics1 like PVC, PU, and silicone to create flexible, safe components such as IV tubing and catheters, balancing cost, performance, and patient safety.

Understanding the properties and applications of these materials is crucial for selecting the right plastic for specific medical devices. Explore further to see how each material performs in different scenarios and the ongoing shift towards safer, more sustainable options.

PVC is the most commonly used plastic in medical extrusion.True

Despite concerns, PVC remains popular due to its cost-effectiveness and versatility.

Silicone is the safest biocompatible plastic for medical use.False

While silicone is highly biocompatible, other materials like PU also offer excellent safety profiles.

- 1. What Are the Common Biocompatible Plastics Used in Medical Extrusion?

- 2. What Are the Steps in the Medical Extrusion Process for Biocompatible Plastics?

- 3. What Are the Key Factors in the Medical Extrusion Process?

- 4. What Are the Applications of Biocompatible Plastics in Medical Extrusion?

- 5. What Are the Differences Between Extrusion and Other Processes for Medical Plastics?

- 6. Conclusion

What Are the Common Biocompatible Plastics Used in Medical Extrusion?

Biocompatible plastics are pivotal in medical extrusion, providing safe, flexible materials for critical devices like IV tubing and catheters.

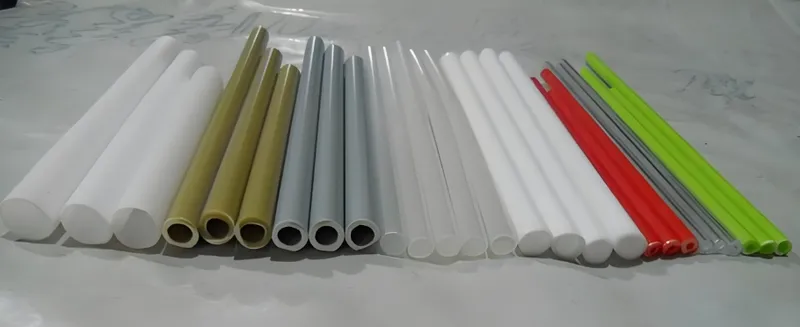

Common biocompatible plastics for medical extrusion include PVC, polyurethane (PU), and silicone2, chosen for their flexibility, safety, and compatibility with medical applications.

| Material | Flexibility | Cost | Biocompatibility | Common Applications |

|---|---|---|---|---|

| PVC | High | Low | Good (with caveats) | IV tubing, catheters |

| PU | Very High | Medium | Excellent | Catheters, tubing |

| Silicone | High | High | Excellent | Respiratory tubing, implants |

Polyvinyl Chloride (PVC)

PVC has been a staple in medical extrusion for decades due to its flexibility and low cost. However, concerns about DEHP plasticizers, which can leach into fluids, have led to a shift towards safer alternatives. Despite this, PVC remains widely used, especially in cost-sensitive applications like disposable IV tubing.

Polyurethane (PU)

PU offers superior flexibility and biocompatibility, making it ideal for long-term applications such as catheters. It is often formulated without plasticizers, reducing the risk of leaching. PU’s excellent chemical resistance and durability make it a preferred choice for devices requiring prolonged contact with bodily fluids.

Silicone

Silicone is known for its high temperature resistance and excellent biocompatibility, making it suitable for respiratory tubing and implants. Its flexibility and inertness ensure minimal interaction with medications or tissues, though its higher cost limits its use to specialized applications.

PVC is being phased out due to safety concerns.True

DEHP plasticizers in PVC have raised toxicity concerns, prompting a shift to safer materials like PU and silicone.

All biocompatible plastics are equally suitable for all medical applications.False

Each plastic has unique properties, making them better suited for specific applications based on flexibility, cost, and safety requirements.

What Are the Steps in the Medical Extrusion Process for Biocompatible Plastics?

The extrusion process for biocompatible plastics is critical in producing safe, high-quality medical devices by shaping polymers into precise, flexible components.

The medical extrusion3 process involves melting the polymer, shaping it through a die, cooling, and sterilizing to create biocompatible components like tubing and catheters.

Material Selection

Choose a biocompatible plastic (e.g., PVC, PU, silicone) based on the application’s requirements for flexibility, cost, and safety. Ensure the material complies with medical standards like ISO 109934.

Extrusion

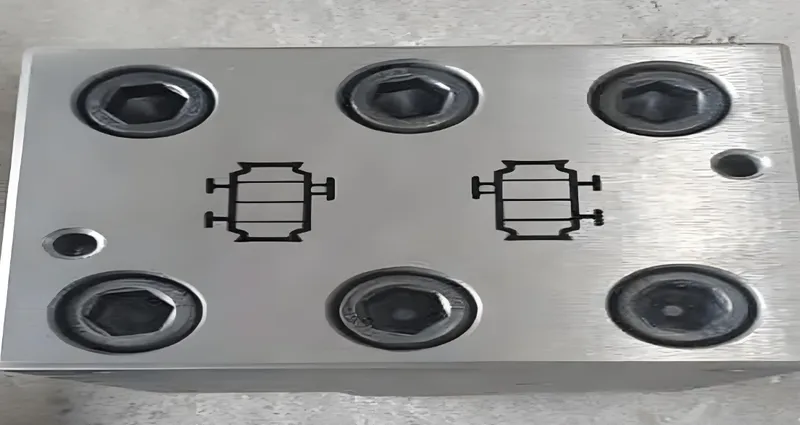

Melt the plastic in an extruder and force it through a die to form the desired shape, such as tubing. For multi-lumen or complex designs, co-extrusion may be used.

Cooling and Sizing

Cool the extruded product to solidify it while maintaining precise dimensions, crucial for medical applications where accuracy is vital.

Inspection and Testing

Inspect for defects and perform biocompatibility tests, including cytotoxicity and sensitization, to ensure the product meets safety standards.

Sterilization

Sterilize the product using methods like steam or gamma radiation, ensuring the material can withstand the process without degradation.

The extrusion process is the same for all biocompatible plastics.False

Each plastic requires specific processing conditions, such as temperature and pressure, to achieve optimal properties.

Sterilization is a critical step in medical extrusion.True

Sterilization ensures the final product is safe for patient use, with methods chosen based on material compatibility.

What Are the Key Factors in the Medical Extrusion Process?

The medical extrusion process for biocompatible plastics relies on precise control of material properties and processing conditions to ensure safety and performance.

Key factors in medical extrusion include material selection, temperature control, and die design, which directly impact the final product’s flexibility, strength, and biocompatibility.

Material Selection

Choosing the right plastic is crucial. PVC requires careful handling due to potential degradation, while silicone needs high temperatures for proper extrusion. Additives like plasticizers (in PVC) or stabilizers can also affect the process and final properties.

Temperature Control

Each plastic has an optimal extrusion temperature. For example, PVC is typically extruded between 140-190°C, while silicone requires higher temperatures. Incorrect temperatures can lead to poor material flow or degradation.

Die Design

The die determines the shape and dimensions of the extruded product. Precision is essential for medical tubing, where even slight variations can affect performance. Multi-lumen dies are used for complex catheter designs.

Processing Speed

The speed of extrusion affects the residence time of the material in the extruder, influencing the final product’s density and strength. Too fast or too slow can lead to defects like bubbles or incomplete melting.

Material selection is the most critical factor in medical extrusion.True

The choice of plastic determines the processing conditions and the final product’s safety and performance.

All biocompatible plastics can be extruded at the same temperature.False

Each plastic has unique thermal properties, requiring specific temperature settings for optimal extrusion.

What Are the Applications of Biocompatible Plastics in Medical Extrusion?

Biocompatible plastics are integral to medical extrusion5, enabling the production of safe, flexible devices essential for patient care.

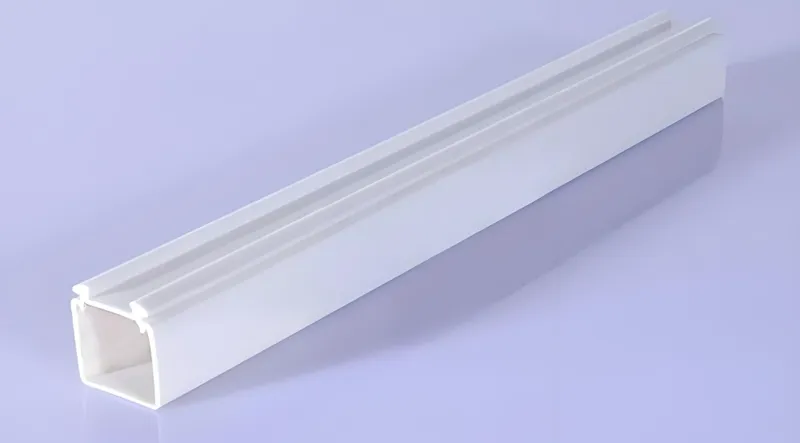

Biocompatible plastics are extruded into IV tubing, catheters, and respiratory hoses, providing flexibility, safety, and compatibility with medical fluids.

IV Tubing

IV tubing, often made from PVC or PU, delivers fluids and medications directly into the bloodstream. Flexibility and clarity are key, allowing healthcare providers to monitor fluid flow.

Catheters

Catheters, typically made from PU or silicone, require high flexibility and biocompatibility for long-term use. They are used in various procedures, from urinary drainage to cardiovascular interventions.

Respiratory Tubing

Silicone is commonly used for respiratory tubing due to its high temperature resistance and inertness, ensuring safe oxygen delivery and compatibility with sterilization methods.

Biocompatible plastics are only used in disposable medical devices.False

While many are disposable, some, like implants, are designed for long-term use, requiring durable, biocompatible materials.

Material choice directly impacts patient safety in medical devices.True

Selecting the right plastic ensures the device is safe, effective, and compatible with the patient’s body.

What Are the Differences Between Extrusion and Other Processes for Medical Plastics?

Extrusion is a key process for producing continuous, uniform medical components, but other methods like injection molding offer distinct advantages for different applications.

Extrusion is ideal for continuous production of tubing, while injection molding is better for complex, discrete parts like connectors or housings.

Extrusion

Extrusion is used for long, uniform products like tubing and hoses. It offers high efficiency and cost-effectiveness for mass production but is limited to simple cross-sectional shapes.

Injection Molding

Injection molding is suited for complex, three-dimensional parts like syringe barrels or catheter hubs. It allows for intricate designs but is less efficient for long, continuous products.

Advantages of Extrusion

Extrusion provides consistent quality and lower costs for high-volume production of tubing. It also allows for co-extrusion, creating multi-layered or multi-lumen designs.

Extrusion is the only process used for medical plastics.False

While extrusion is common for tubing, other processes like injection molding are essential for more complex medical components.

Extrusion offers cost advantages for large-scale production.True

The continuous nature of extrusion reduces material waste and labor costs, making it ideal for mass production.

Conclusion

Biocompatible plastics like PVC, PU, and silicone play a vital role in medical extrusion, each offering unique benefits and challenges. As the industry moves towards safer and more sustainable materials, we can expect continued innovation in biocompatible plastics6 and extrusion technologies. Understanding these materials and processes is key to advancing medical device manufacturing and improving patient outcomes.

-

Explore the advantages of biocompatible plastics in medicine, including safety and flexibility, to understand their critical role in healthcare. ↩

-

Discover the unique properties and applications of PVC, PU, and silicone to make informed choices for medical device materials. ↩

-

Learn about the medical extrusion process and its significance in creating safe medical devices using biocompatible plastics. ↩

-

Learn about ISO 10993 standards to ensure your materials meet essential biocompatibility requirements for medical devices, enhancing safety and compliance. ↩

-

This resource will provide insights into the medical extrusion process, highlighting its significance in producing safe and effective medical devices. ↩

-

Explore this link to understand the latest advancements and applications of biocompatible plastics in the medical field, ensuring safety and effectiveness. ↩