Conductive plastics are transforming industries by merging the versatility of plastics with the ability to conduct electricity. These innovative materials are particularly valuable in extrusion, a manufacturing process that shapes molten material into continuous forms like tubes, sheets, and profiles. In this post, we’ll dive into how conductive plastics1 are applied in extrusion, exploring their properties, processes, and real-world uses.

Conductive plastics, enhanced with fillers like carbon black, are extruded to create lightweight, electrically conductive products for electronics, automotive, and more.

Understanding the role of conductive plastics in extrusion can unlock new possibilities for lightweight, cost-effective solutions. Let’s explore the materials, steps, and applications that make this technology a game-changer.

Conductive plastics reduce material costs in manufacturing.True

By combining conductivity with lightweight properties, they offer savings over heavier metals.

Conductive plastics are only used in niche industries.False

Beyond electronics, they’re widely applied in automotive, packaging, and other sectors.

- 1. What Are Conductive Plastics and How Are They Used in Extrusion?

- 2. What Are the Steps in the Extrusion Process for Conductive Plastics?

- 3. What Are the Key Factors in Extruding Conductive Plastics?

- 4. What Are the Applications of Conductive Plastics in Extrusion?

- 5. How Do Conductive Plastics Compare to Metals in Extrusion?

- 6. Practical Tools for Extruding Conductive Plastics

- 7. Conclusion

What Are Conductive Plastics and How Are They Used in Extrusion?

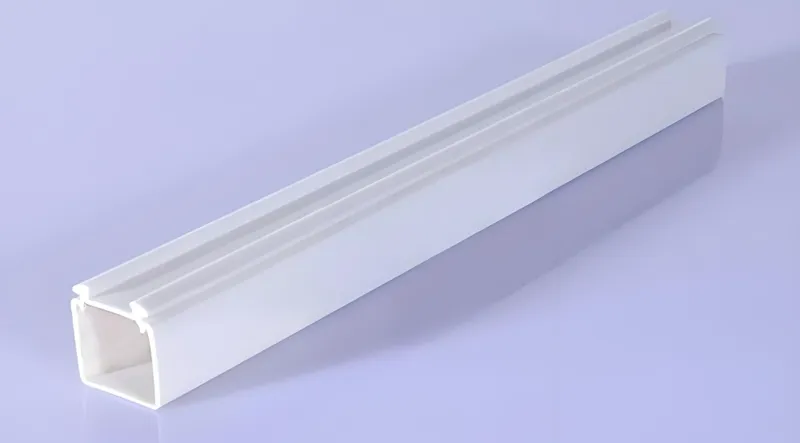

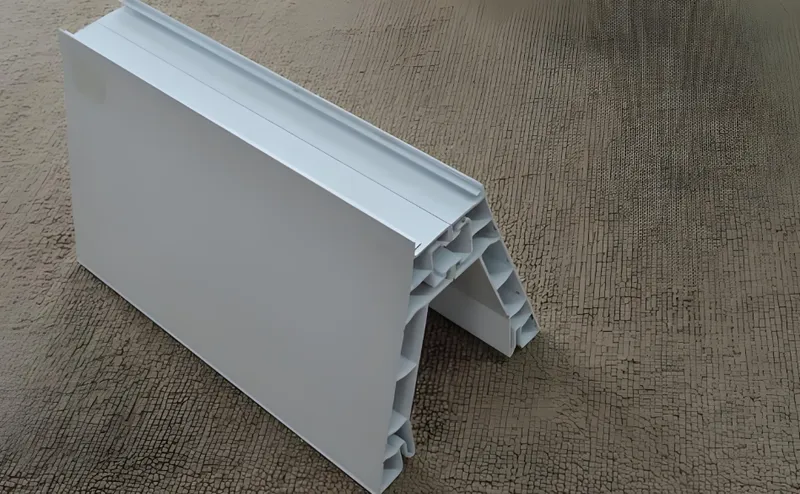

Conductive plastics are polymers engineered to conduct electricity, typically by adding fillers such as carbon black, graphite, or metal particles. In extrusion, these materials are melted and pushed through a die to form continuous shapes, making them ideal for products needing both flexibility and electrical functionality.

Conductive plastics, or electrically conductive polymers2, are extruded into forms like antistatic sheets and EMI shielding components, blending plastic’s adaptability with electrical performance.

| Material Type | Common Fillers | Applications |

|---|---|---|

| Polypropylene (PP) | Carbon black, graphite | ESD packaging, automotive |

| Polystyrene (PS) | Carbon black, metal fibers | EMI shielding, electronics |

| Polyurethane (TPU) | Carbon nanotubes, graphite | Conductive hoses, gaskets |

Defining Conductive Plastics

Conductive plastics, also called electrically conductive polymers, combine the insulating nature of traditional plastics with electrical conductivity. This is achieved either by mixing in conductive fillers or using inherently conductive polymers like polyaniline. Learn more at RTP Company.

Extrusion: The Process Explained

Extrusion involves melting a material and forcing it through a die to create uniform, continuous shapes. For conductive plastics, this process ensures consistent electrical properties across long profiles, serving industries from electronics to automotive.

All conductive plastics use carbon-based fillers.False

While carbon black is common, metal particles and conductive polymers are also options.

Extrusion ensures uniform conductivity in conductive plastics.True

The continuous process distributes fillers evenly, maintaining consistent electrical properties.

What Are the Steps in the Extrusion Process for Conductive Plastics?

Extruding conductive plastics requires a precise sequence of steps to balance conductivity, shape, and durability.

The extrusion process3 for conductive plastics includes material selection, compounding, melting, shaping, cooling, and post-processing, delivering products with reliable electrical and mechanical properties.

1. Material Selection

Select a base polymer (e.g., polyethylene) and a conductive filler (e.g., carbon black) based on the desired conductivity and strength.

2. Compounding

Blend the polymer and filler to ensure even distribution. This step, detailed by RTP Company, is vital for uniform conductivity.

3. Extrusion

- Melting: The compounded material is fed into an extruder and melted.

- Shaping: The molten mix is pushed through a die to form shapes like tubes or sheets.

- Parameters: Temperature (150–300°C), pressure, and screw speed are fine-tuned.

4. Cooling

The shaped material is cooled with water or air to solidify its form, preventing distortion due to plastics’ low thermal conductivity.

5. Post-Processing

The product is cut, trimmed, or treated for specific uses, such as surface finishing for EMI shielding.

Compounding is optional in extrusion.False

Proper compounding ensures fillers are evenly dispersed, critical for conductivity.

Cooling affects the final shape of extruded conductive plastics.True

Controlled cooling prevents warping and maintains structural integrity.

What Are the Key Factors in Extruding Conductive Plastics?

Success in extruding conductive plastics hinges on several critical factors.

Key factors include polymer choice4, filler type5, temperature, and screw speed, all influencing the product’s conductivity and quality.

Base Polymer Choice

Polymers like polypropylene offer flexibility, while polystyrene provides rigidity. The choice shapes the product’s mechanical traits.

Filler Type and Concentration

Fillers like carbon black or graphite determine conductivity levels. Higher concentrations boost conductivity but may stiffen the material.

Extrusion Temperature

Temperature must melt the polymer without degrading the filler, typically ranging from 150–300°C.

Screw Speed

Screw speed controls how long the material stays in the extruder, affecting filler dispersion and consistency.

More filler always means better conductivity.False

Excess filler can compromise flexibility without improving conductivity further.

Temperature control is essential for quality extrusion.True

Proper temperature ensures filler dispersion and prevents material degradation.

What Are the Applications of Conductive Plastics in Extrusion?

Extruded conductive plastics serve a wide range of industries, offering lightweight, conductive solutions.

Conductive plastics are extruded for ESD protection, EMI shielding, and antistatic parts in electronics, automotive, and packaging.

Electronics

Antistatic packaging and EMI shielding components protect sensitive devices from static and interference.

Automotive

Conductive hoses and gaskets dissipate static in fuel systems, enhancing safety.

Packaging

Extruded sheets provide antistatic protection for electronics and other static-sensitive goods.

Conductive plastics are limited to electronics.False

They’re also used in automotive and packaging for their versatility.

Extruded conductive plastics excel in ESD protection.True

Their uniform conductivity makes them ideal for static dissipation.

How Do Conductive Plastics Compare to Metals in Extrusion?

Conductive plastics offer distinct advantages over metals, though they have trade-offs.

Compared to metals, conductive plastics are lighter and corrosion-resistant but have lower conductivity, suiting them for specific uses.

Advantages

-

Lightweight: Reduces shipping and material costs.

-

Corrosion Resistance: Outlasts metals in harsh environments.

-

Flexibility: Easily shaped into complex profiles.

Disadvantages

-

Lower Conductivity: Less effective for high-current needs.

-

Heat Sensitivity: Limited in extreme temperature settings.

Conductive plastics outperform metals in all applications.False

Metals excel in high-conductivity scenarios, but plastics win in weight and flexibility.

Conductive plastics resist corrosion better than metals.True

Unlike metals, they don’t rust, extending product life.

Practical Tools for Extruding Conductive Plastics

These tools can guide your work with conductive plastics in extrusion.

A design checklist and process guide help optimize material selection, filler levels, and extrusion settings.

Design Checklist

-

Conductivity Needs: Set resistance targets (e.g., 10^2–10^6 Ohms).

-

Polymer Selection: Match mechanical properties to the application.

-

Filler Choice: Balance cost and conductivity with fillers like graphite.

-

Process Settings: Optimize temperature and speed.

-

End-Use Conditions: Account for temperature, humidity, and regulations.

Process Selection Guide

-

Shape: Extrusion suits continuous forms like sheets.

-

Volume: Ideal for high-output production.

-

Cost: Compare with alternatives like molding for small runs.

A checklist improves extrusion outcomes.True

It addresses key variables, reducing errors and enhancing quality.

Extrusion is the only option for conductive plastics.False

Injection molding may suit discrete parts better.

Conclusion

Conductive plastics in extrusion blend lightweight flexibility with electrical conductivity, offering valuable solutions for electronics, automotive, and beyond. By mastering the materials and process, you can harness these materials for innovative, cost-effective designs.

-

Explore how conductive plastics are revolutionizing industries with their unique properties and applications. ↩

-

Learn about electrically conductive polymers and how they enhance product functionality across various applications. ↩

-

Understanding the extrusion process can provide insights into the manufacturing of innovative conductive plastic products. ↩

-

Understanding polymer choice is crucial for optimizing the mechanical and electrical properties of conductive plastics in your projects. ↩

-

Learn how different fillers can enhance or modify the conductivity of plastics, crucial for achieving desired performance in applications. ↩