Surface defects in extrusion can be a major headache, but with the right approach, you can avoid them and produce top-notch products. Whether it’s rough surfaces, cracks, or blisters, these imperfections not only affect the appearance of your products but can also compromise their functionality and structural integrity. In this post, we’ll dive into the causes of surface defects, how to prevent them, and why extrusion remains a go-to process for industries like automotive, construction, and medical devices.

Preventing surface defects in extrusion1 requires controlling material preparation, process parameters, and die maintenance, ensuring high-quality products for industries like automotive and construction.

Understanding the root causes and implementing best practices can save you time, reduce waste, and improve your bottom line. Let’s explore how to achieve flawless extrusion results.

Proper material preparation is crucial for preventing surface defects.True

Ensuring materials are dry and contaminant-free reduces the risk of defects like bubbles and discoloration.

Extrusion is always the best choice for high surface quality.False

While extrusion can achieve good surface quality, other processes like machining may be better for certain applications.

- 1. What Are the Common Causes of Surface Defects in Extrusion?

- 2. What Are the Steps to Prevent Surface Defects in Extrusion?

- 3. What Are the Key Factors in Preventing Surface Defects?

- 4. What Are the Applications Where Surface Quality Is Critical in Extrusion?

- 5. How Does Extrusion Compare to Other Processes for Surface Quality?

- 6. Conclusion

What Are the Common Causes of Surface Defects in Extrusion?

Surface defects in extrusion can derail your production, leading to costly rework or scrapped materials. Identifying the root causes is the first step to preventing these issues.

Common causes of surface defects in extrusion include improper material preparation, incorrect processing conditions, and die-related issues, which can lead to rough surfaces, cracks, or blisters.

| Defect Type | Common Causes |

|---|---|

| Rough Surface | Unmelted particles, high screw speed, inconsistent temperatures |

| Cracks | Inadequate heating, rapid cooling, high extrusion speed |

| Blisters | Moisture in material, trapped air, poor material drying |

| Discoloration | Overheating, contamination, incorrect temperature settings |

| Die Lines | Worn or damaged die, high material viscosity, improper die design |

Improper Material Preparation

Materials that aren’t properly dried or contain contaminants can introduce defects like bubbles or discoloration. For example, moisture in thermoplastics can vaporize during extrusion, creating voids or blisters on the surface, as noted in 12 Extrusion Defects and Troubleshooting.

Incorrect Processing Conditions

Inconsistent temperatures, pressures, or extrusion speeds can lead to defects such as melt fracture or surface roughness. High shear rates, often caused by excessive screw speed, can result in a wavy, rough surface known as melt fracture, according to Common Extrusion Defects & Solutions.

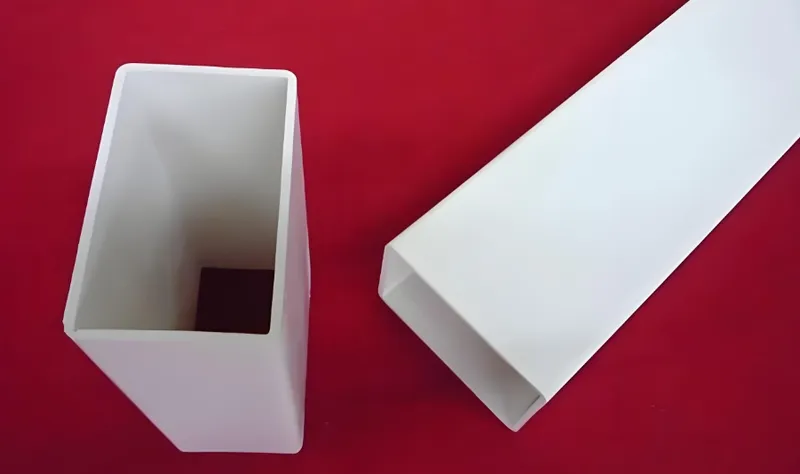

Die-Related Issues

A worn or poorly designed die can cause uneven material flow, leading to defects like die lines or surface irregularities. Regular die maintenance is essential for a smooth, uniform finish, as emphasized in Minimizing Defects in Aluminum Extrusion.

Surface defects are always caused by material issues.False

While material preparation is crucial, processing conditions and die maintenance also play significant roles in defect prevention.

Die maintenance is essential for achieving a smooth surface finish.True

A well-maintained die ensures uniform material flow, reducing the risk of defects like die lines or surface roughness.

What Are the Steps to Prevent Surface Defects in Extrusion?

Preventing surface defects in extrusion requires a proactive approach, focusing on key areas that directly impact the quality of your final product.

To prevent surface defects in extrusion, focus on proper material preparation, precise process control, and regular die maintenance2, ensuring consistent quality in your products.

Material Preparation

Ensure your materials are dry and free from contaminants. For thermoplastics, proper drying eliminates moisture-related defects like bubbles or voids. Use clean, high-quality materials to avoid contamination that could lead to discoloration or surface irregularities.

Process Control

Maintain consistent temperatures, pressures, and extrusion speeds. Set the correct temperature profile along the barrel for uniform melting and control screw speed to avoid high shear rates that cause melt fracture. Adjust parameters to match material requirements, as detailed in Factors That Make or Break Plastic Extrusion Quality.

Die Maintenance

Regularly inspect and clean dies to prevent wear or obstructions that disrupt material flow. Use smooth, polished dies for a uniform surface finish and optimize die design3 for consistent extrusion, as recommended in Minimizing Defects in Aluminum Extrusion.

Consistent process parameters guarantee defect-free extrusion.False

While important, process control must be combined with material preparation and die maintenance for optimal results.

Proper die maintenance can reduce surface defects by up to 50%.True

A well-maintained die ensures uniform material flow, significantly reducing the risk of defects.

What Are the Key Factors in Preventing Surface Defects?

Preventing surface defects in extrusion hinges on controlling specific factors that influence the quality of the final product.

Key factors in preventing surface defects include material selection, temperature control4, and die design, which directly impact the extrusion process and product quality.

Material Selection

Different materials require tailored handling to avoid defects. Thermoplastics need precise temperature control to prevent degradation, while metals may require lubrication to avoid surface tearing, as noted in Extrusion Parameter Overview.

Temperature Control

Maintaining the right temperature profile is critical. Too high or too low temperatures can cause defects like rough surfaces or cracks. Ensure uniform heating and cooling to avoid issues such as melt fracture or warping, per Common Extrusion Defects & Solutions.

Die Design

A well-designed die ensures uniform material flow, reducing defect risks. Consider die surface finish, land length, and entry angle to optimize flow and minimize irregularities, as discussed in Minimizing Defects in Aluminum Extrusion.

Material selection has no impact on surface defects.False

Different materials have unique properties that require specific handling to prevent defects.

Proper die design can eliminate all surface defects.False

While crucial, die design must be combined with other factors like material preparation and process control.

What Are the Applications Where Surface Quality Is Critical in Extrusion?

Surface quality in extrusion is paramount in industries where appearance and functionality depend on a flawless finish.

Industries like automotive, construction, and medical devices rely on extrusion for parts where surface defects5 can lead to functional failures or safety hazards.

Automotive Industry

Extrusion produces parts like bumper reinforcements, weatherstripping, and interior trim. Surface defects can affect fit, finish, and durability, potentially leading to costly rework or recalls.

Construction Industry

Pipes, profiles, and insulation materials depend on extrusion. Defects like cracks or rough surfaces can compromise structural integrity, causing leaks or system failures.

Medical Devices

Medical tubing and catheters require impeccable surface quality for sterility and performance. Defects can introduce contamination risks or impair functionality, as highlighted in Surface Defect Overview.

Surface quality is only important for aesthetic reasons.False

In many industries, surface defects can lead to functional failures or safety issues, not just aesthetic concerns.

Extrusion is widely used in industries where surface quality is critical.True

Industries like automotive and medical devices rely on extrusion for high-quality, defect-free components.

How Does Extrusion Compare to Other Processes for Surface Quality?

Extrusion offers unique advantages for long, continuous parts, but it may need extra steps to match the surface quality of other processes.

Extrusion is cost-effective for long, continuous parts but may need post-processing for high surface quality, unlike machining or injection molding, which can achieve finer finishes directly.

Extrusion vs. Injection Molding

Injection molding excels at complex shapes with high surface finishes straight from the mold but is less efficient for long profiles, where extrusion shines, per Surface Roughness Comparison.

Extrusion vs. Machining

Machining delivers very smooth surfaces but is costly and slow for large parts. Extrusion, while potentially needing post-processing, is more efficient for high-volume production, as noted in Surface Finish Chart.

Extrusion vs. Casting

Casting often produces rougher surfaces and is less suited for high-quality finishes. Extrusion, with proper control, offers smoother, more consistent results, according to Environmental Comparison of Processes).

Extrusion always produces better surface quality than casting.True

Extrusion typically results in smoother surfaces compared to casting, which often requires additional finishing.

Injection molding is more cost-effective than extrusion for long parts.False

Extrusion is generally more cost-effective for producing long, continuous parts compared to injection molding.

Conclusion

Preventing surface defects in extrusion is essential for delivering high-quality products that meet industry standards. By prioritizing proper material preparation, precise process control, and regular die maintenance, you can avoid common issues like rough surfaces, cracks, and blisters. While extrusion is cost-effective for long, continuous parts, it may require additional finishing to rival the surface quality of processes like machining or injection molding.

-

Understanding surface defects in extrusion is crucial for maintaining product quality. Explore this link to learn effective prevention strategies. ↩

-

Die maintenance is vital for ensuring smooth extrusion and preventing defects. Learn more about its significance and best practices here. ↩

-

Effective die design is key to achieving high-quality extrusions; explore best practices to enhance your production process. ↩

-

Temperature control is crucial for ensuring the quality of extruded products; learn how to optimize it for better results. ↩

-

Understanding the causes of surface defects can help improve product quality and reduce waste in manufacturing. ↩