Warping in extruded products is a common issue that can compromise the quality and functionality of the final product. It occurs when the material distorts or bends due to uneven cooling1 or internal stresses during the extrusion process. This defect is prevalent in both 3D printing and traditional manufacturing, such as plastic profile extrusion, and can affect a wide range of applications, from construction pipes to automotive components.

Preventing warping in extruded products involves uniform cooling, selecting materials with low thermal expansion, designing for consistent thickness, and controlling extrusion parameters like temperature and speed.

Understanding the causes of warping and implementing effective prevention strategies is crucial for manufacturers aiming to produce high-quality extruded products. This article delves into the key factors that contribute to warping and provides actionable insights to mitigate this issue.

Uniform cooling is the most critical factor in preventing warping.True

Ensuring even cooling rates across the extruded product minimizes differential shrinkage, which is a primary cause of warping.

All materials are equally prone to warping during extrusion.False

Materials with higher coefficients of thermal expansion, like polypropylene, are more susceptible to warping compared to those with lower CTE, such as polycarbonate.

- 1. What are the Common Causes of Warping in Extruded Products?

- 2. What are the Key Strategies to Prevent Warping in Extruded Products?

- 3. How Does Material Selection Impact Warping in Extruded Products?

- 4. What are the Best Practices for Designing Extruded Products to Prevent Warping?

- 5. How Can Process Control Mitigate Warping in Extruded Products?

- 6. What are the Applications Where Warping Prevention is Critical?

- 7. Conclusion

What are the Common Causes of Warping in Extruded Products?

Warping in extruded products is a prevalent issue that can significantly affect the quality and functionality of the final product. Understanding the root causes of warping is essential for manufacturers to implement effective prevention strategies.

Warping in extruded products is primarily caused by uneven cooling, material shrinkage, and internal stresses2, leading to distortion and bending from the intended shape.

| Cause | Impact on Warping | Prevention Strategy |

|---|---|---|

| Uneven Cooling | Differential shrinkage causes bending | Use uniform cooling systems (e.g., water baths) |

| Material Shrinkage | High shrinkage rates lead to distortion | Select materials with low CTE |

| Internal Stresses | Stress concentrations cause warping | Design for uniform thickness |

Uneven Cooling

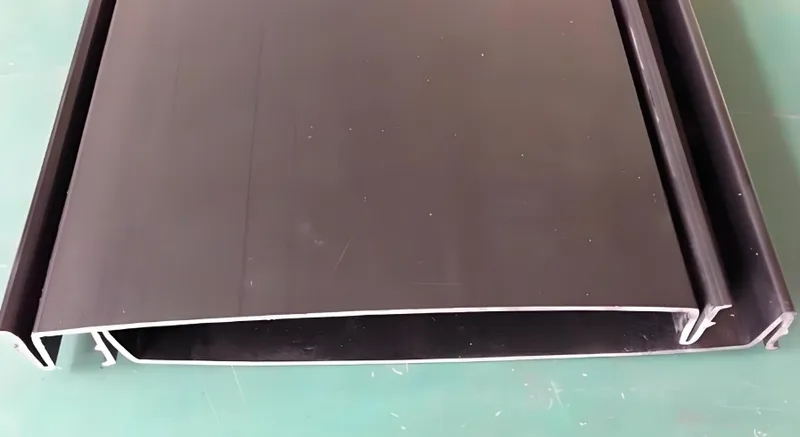

Uneven cooling is a major contributor to warping in extruded products. When different parts of the extruded material cool at different rates, it leads to differential shrinkage. This uneven shrinkage causes the material to bend or distort, resulting in warping. For instance, in plastic profile extrusion, if one side of the profile cools faster than the other, it can lead to curvature or twisting.

Material Shrinkage

Materials with high coefficients of thermal expansion (CTE) are more prone to warping due to greater shrinkage during cooling. For example, polypropylene (PP) has a high shrinkage rate, making it more susceptible to warping compared to materials like polycarbonate (PC), which has a lower CTE. The choice of material significantly impacts the likelihood of warping, especially in applications requiring high dimensional accuracy.

Internal Stresses

Internal stresses within the extruded product can also cause warping. These stresses often arise from non-uniform cross-sections or complex geometries that create stress concentrations. When the material is cooled, these stresses can lead to distortion. Designing products with uniform thickness and avoiding sharp corners can help minimize internal stresses and reduce the risk of warping.

Warping only occurs in plastic extrusion processes.False

While common in plastics, warping can also occur in metal extrusion due to similar thermal and mechanical factors.

Material selection has no impact on warping.False

Choosing materials with low thermal expansion coefficients can significantly reduce the likelihood of warping.

What are the Key Strategies to Prevent Warping in Extruded Products?

Preventing warping in extruded products is crucial for maintaining product quality and functionality. By implementing effective strategies, manufacturers can minimize the risk of distortion and ensure consistent results.

Key strategies to prevent warping in extruded products include ensuring uniform cooling, selecting appropriate materials, designing for consistent thickness, and controlling extrusion parameters.

Uniform Cooling

Ensuring uniform cooling is paramount in preventing warping. Uneven cooling leads to differential shrinkage, causing the material to bend or distort. Techniques such as using water baths, air cooling systems, or cooling fixtures can help achieve even cooling rates across the extruded product. For example, in plastic profile extrusion, immersing the extruded profile in a water bath can promote uniform cooling and reduce the risk of warping.

Material Selection

Choosing materials with low coefficients of thermal expansion3 (CTE) can significantly reduce the likelihood of warping. Materials like polycarbonate (PC) have lower CTE compared to polypropylene (PP) or acrylonitrile butadiene styrene (ABS), making them less prone to shrinkage and distortion during cooling. Selecting the right material based on the application’s requirements is essential for minimizing warping risks.

Design Considerations

Designing products with consistent thickness helps avoid stress concentrations that can lead to warping. Uniform cross-sections ensure even cooling and reduce the likelihood of internal stresses. Additionally, avoiding sharp corners and complex geometries can further minimize the risk of distortion. For instance, in 3D printing, designing parts with gradual transitions and avoiding overhangs can help prevent warping.

Process Control

Carefully managing extrusion parameters such as temperature and speed is crucial for preventing warping. Setting the extrusion temperature appropriately can reduce internal stresses, while controlling the cooling rate ensures it is neither too fast nor too slow. For example, in plastic extrusion, maintaining a consistent extrusion speed and optimizing the cooling system can help achieve better outcomes.

Designing products with varying thicknesses can help reduce warping.False

Varying thicknesses can lead to uneven cooling and stress concentrations, increasing the risk of warping.

Uniform cooling alone is sufficient to prevent warping in all cases.False

While uniform cooling is critical, other factors like material selection and design also play significant roles in preventing warping.

How Does Material Selection Impact Warping in Extruded Products?

Material selection plays a pivotal role in determining the likelihood of warping in extruded products. Different materials exhibit varying degrees of thermal expansion4 and shrinkage, which directly influence the risk of distortion.

Material selection impacts warping in extruded products by influencing thermal expansion and shrinkage rates, with materials like polycarbonate offering lower warping risks compared to polypropylene.

| Material | CTE (Coefficient of Thermal Expansion) | Warping Risk | Typical Applications |

|---|---|---|---|

| Polypropylene (PP) | High | High | Pipes, containers |

| Polycarbonate (PC) | Low | Low | Window frames, automotive |

| Acrylonitrile Butadiene Styrene (ABS) | Medium | Medium | Consumer goods, 3D printing |

Thermal Expansion and Shrinkage

Materials with high coefficients of thermal expansion (CTE) are more susceptible to warping due to greater shrinkage during cooling. For instance, polypropylene (PP) has a high CTE, leading to significant shrinkage and a higher risk of warping. In contrast, polycarbonate (PC) has a lower CTE, resulting in less shrinkage and a reduced likelihood of distortion. Selecting materials with lower CTE is crucial for applications requiring high dimensional accuracy.

Material Properties and Applications

Different materials are suited for specific applications based on their properties. For example, PP is commonly used in pipes and containers due to its flexibility, but its high warping risk necessitates careful process control. PC, with its low warping risk, is ideal for window frames and automotive parts where dimensional stability is critical. Understanding the material properties and their impact on warping can guide manufacturers in selecting the most appropriate material for their needs.

All thermoplastics have the same likelihood of warping.False

Thermoplastics vary in their CTE and shrinkage rates, leading to different warping tendencies.

Material selection is the only factor influencing warping.False

While material selection is important, other factors like cooling uniformity and design also significantly impact warping.

What are the Best Practices for Designing Extruded Products to Prevent Warping?

Designing extruded products with warping prevention5 in mind is essential for ensuring the final product meets quality standards. By following best practices, manufacturers can minimize the risk of distortion and improve overall product performance.

Best practices for designing extruded products to prevent warping include maintaining uniform thickness, avoiding complex geometries, and incorporating gradual transitions.

Uniform Thickness

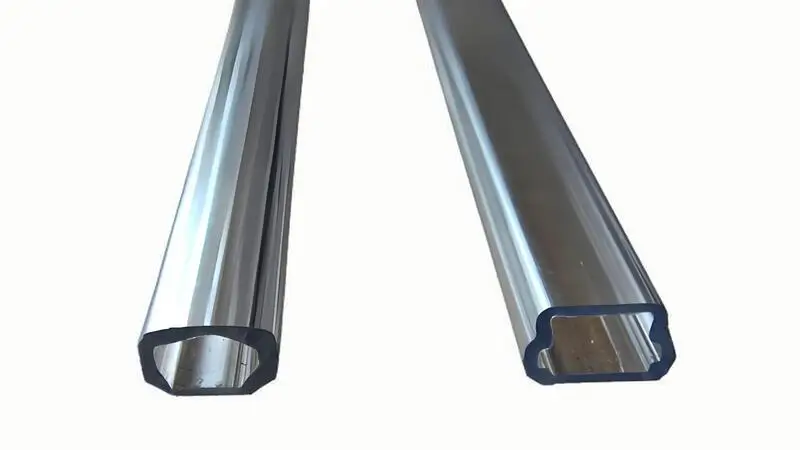

Designing products with consistent thickness ensures even cooling and reduces the likelihood of stress concentrations. Uniform cross-sections help distribute thermal and mechanical stresses evenly, minimizing the risk of warping. For example, in plastic profile extrusion, maintaining a constant wall thickness throughout the profile can prevent differential shrinkage and distortion.

Avoiding Complex Geometries

Complex geometries, such as sharp corners or intricate details, can create stress points and lead to uneven cooling. Simplifying the design by avoiding these features can help reduce the risk of warping. In 3D printing, for instance, using fillets instead of sharp corners can promote more uniform cooling and reduce internal stresses.

Incorporating Gradual Transitions

Incorporating gradual transitions in the design, such as tapered sections or smooth curves, can help distribute stresses more evenly and promote uniform cooling. This approach is particularly effective in reducing warping in products with varying cross-sections. For example, in extruded pipes, using gradual transitions between different diameters can minimize stress concentrations and prevent distortion.

Designing with varying thicknesses can enhance product strength without causing warping.False

Varying thicknesses can lead to uneven cooling and increased warping risk, outweighing any potential strength benefits.

Simplifying geometries always compromises product functionality.False

Simplifying geometries can enhance manufacturability and reduce warping without necessarily compromising functionality.

How Can Process Control Mitigate Warping in Extruded Products?

Process control is a critical aspect of preventing warping in extruded products. By carefully managing extrusion parameters, manufacturers can optimize the process and minimize the risk of distortion.

Process control mitigates warping in extruded products by optimizing extrusion temperature, controlling cooling rates, and maintaining consistent extrusion speed.6

| Parameter | Impact on Warping | Recommended Action |

|---|---|---|

| Extrusion Temperature | High temps reduce stress, risk degradation | Optimize for material, avoid overheating |

| Cooling Rate | Uneven cooling causes warping | Use uniform cooling systems (e.g., water baths) |

| Extrusion Speed | Inconsistent speed leads to uneven cooling | Maintain consistent speed |

Optimizing Extrusion Temperature

Setting the extrusion temperature appropriately is crucial for reducing internal stresses that can lead to warping. Higher temperatures can help minimize stresses but risk thermal degradation of the material. It’s essential to find the optimal temperature range for the specific material being used. For example, in plastic extrusion, maintaining the barrel temperature within the recommended range for the polymer can help achieve better results.

Controlling Cooling Rates

Controlling the cooling rate ensures that the extruded product cools uniformly, preventing differential shrinkage and warping. Using cooling systems such as water baths or air knives can help achieve even cooling. The cooling rate should be neither too fast nor too slow; rapid cooling can cause brittleness, while slow cooling can lead to excessive shrinkage. For instance, in 3D printing, using a heated bed can help control the cooling rate and reduce warping.

Maintaining Consistent Extrusion Speed

Maintaining a consistent extrusion speed is important for ensuring uniform cooling and reducing the risk of warping.7 Inconsistent speed can lead to variations in the cooling rate, causing differential shrinkage and distortion. For example, in plastic profile extrusion, using a haul-off system to control the speed can help achieve consistent results.

Higher extrusion temperatures always reduce warping.False

While higher temperatures can reduce internal stresses, they can also risk thermal degradation, which may compromise product quality.

Controlling cooling rates is more important than material selection in preventing warping.False

Both cooling rates and material selection are crucial; neglecting either can lead to warping.

What are the Applications Where Warping Prevention is Critical?

Preventing warping is particularly critical in applications where dimensional accuracy and structural integrity are paramount. These applications span various industries, each with unique requirements for extruded products.

Warping prevention is critical in construction, automotive, and consumer goods industries, where dimensional accuracy and structural integrity are essential.8

Construction

In construction, extruded products such as pipes, window frames, and door frames require high dimensional stability to ensure proper fit and function. Warping can compromise the integrity of these components, leading to installation issues and reduced performance. For example, warped window frames may not seal properly, affecting energy efficiency and weather resistance.

Automotive

The automotive industry relies on extruded products for interior and exterior parts, such as trim components and seals. Warping in these parts can affect the aesthetics and functionality of the vehicle. For instance, warped interior trims may not align correctly, leading to gaps and poor fitment. Ensuring dimensional accuracy through warping prevention is crucial for maintaining quality standards.

Consumer Goods

Consumer goods, such as packaging containers and household items, also benefit from warping prevention. Warped containers may not stack properly or seal effectively, impacting their usability and appeal. For example, in food packaging, warped lids may not close tightly, leading to spoilage or contamination.

Warping prevention is only important in high-precision industries.False

While critical in high-precision industries, warping prevention is also important in consumer goods and construction for functionality and aesthetics.

All extruded products are equally affected by warping.False

The impact of warping varies based on the application and the specific requirements for dimensional accuracy and structural integrity.

Conclusion

Preventing warping in extruded products is essential for ensuring product quality and functionality across various industries. By implementing strategies such as uniform cooling, selecting appropriate materials, designing for consistent thickness, and controlling extrusion parameters, manufacturers can minimize the risk of distortion and achieve consistent results. Understanding the causes of warping and applying best practices in design and process control are key to producing high-quality extruded products.

-

Understanding the effects of uneven cooling can help manufacturers implement better cooling strategies to prevent warping. ↩

-

Learning about internal stresses can help manufacturers design products that are less prone to warping and distortion. ↩

-

Exploring the impact of thermal expansion coefficients can guide material selection to minimize warping in products. ↩

-

Understanding thermal expansion is crucial for selecting materials that minimize warping risks in manufacturing processes. ↩

-

Exploring warping prevention strategies can enhance product quality and performance in manufacturing. ↩

-

Explore this resource to understand how effective process control can significantly reduce warping in extruded products, ensuring quality and performance. ↩

-

This link will provide insights into the importance of consistent extrusion speed in preventing warping, crucial for product integrity. ↩

-

Discover why preventing warping is vital for maintaining quality and safety in construction and automotive applications, impacting overall performance. ↩