Extrusion is a widely used manufacturing process that shapes materials like plastics and metals into continuous profiles, such as pipes, sheets, or rods, by forcing them through a die. A key factor in achieving high-quality extrusion is the careful adjustment of temperature profiles1—the specific temperature settings across different zones of the extruder. Properly tuned temperature profiles ensure that the material melts uniformly, flows smoothly, and forms a product with the desired properties. This blog post will guide you through the essentials of adjusting temperature profiles for optimal extrusion, offering insights for beginners and seasoned professionals alike.

Adjusting temperature profiles in extrusion ensures even melting, smooth flow, and high-quality products by tailoring temperatures across the feed zone, barrel zones, and die to the material and application.

Whether you’re producing packaging films or automotive parts, understanding how to tweak these settings can make all the difference. Let’s dive into the fundamentals, technical details, and practical tips to master this critical aspect of extrusion.

Temperature profiles are essential for successful extrusion.True

They regulate material melting and flow, preventing defects and ensuring consistent product quality.

Extrusion is limited to plastic materials.False

Extrusion is used for plastics, metals, ceramics, and more, across industries like construction and electronics.

- 1. What Are Temperature Profiles in Extrusion?

- 2. How Do Materials Influence Temperature Profiles?

- 3. What Are the Steps to Adjust Temperature Profiles?

- 4. What Challenges Arise in Temperature Profile Adjustments?

- 5. How Do Temperature Profiles Vary by Industry?

- 6. What are Some Practical Tips for Optimizing Temperature Profiles?

- 7. Conclusion

What Are Temperature Profiles in Extrusion?

Temperature profiles refer to the controlled temperature settings along the extruder’s zones: the feed zone, barrel zones, and die zone. Each zone plays a unique role in transforming raw material into a finished product.

Temperature profiles consist of the feed zone (cooler), barrel zones (gradually hotter), and die zone (optimized for shaping), each tailored to ensure proper melting and flow.

| Zone | Typical Temperature Range (e.g., Plastics) | Purpose |

|---|---|---|

| Feed Zone | 20-60°C below softening point | Prevents premature melting |

| Barrel Zones | 150-250°C (material-dependent) | Melts and mixes material |

| Die Zone | 50-75°C above melting point | Shapes and stabilizes flow |

Feed Zone

The feed zone2 introduces raw material into the extruder. It’s kept cooler—often 20-60°C below the material’s softening point—to prevent premature melting, which could clog the system or disrupt feeding consistency.

Barrel Zones

The barrel, divided into multiple zones, gradually heats the material to its melting point. For example, in plastic extrusion, temperatures might start just above the melting point and increase across zones to ensure thorough melting and mixing. This gradual rise is key to avoiding thermal shock and achieving uniformity.

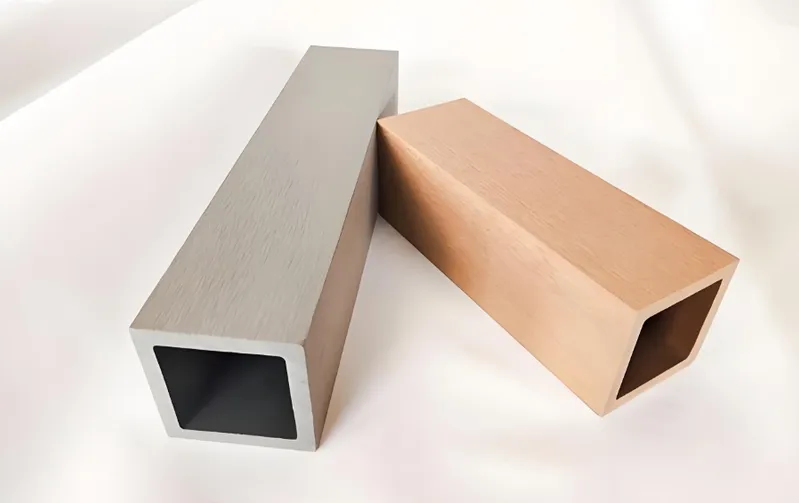

Die Zone

The die zone shapes the molten material as it exits the extruder. Its temperature, often 50-75°C above the material’s melting point, ensures smooth flow and proper shape retention. Too high or too low a setting here can affect surface finish and dimensional accuracy.

The feed zone should be hotter than the barrel zones.False

The feed zone is cooler to avoid early melting, while barrel zones increase in temperature to melt the material.

Die zone temperature affects product surface quality.True

It controls how the material flows and solidifies, impacting smoothness and appearance.

How Do Materials Influence Temperature Profiles?

Different materials—plastics like polyethylene or metals like aluminum—have unique thermal properties, requiring customized temperature profiles for optimal extrusion.

Materials such as polyethylene, PVC, and aluminum demand specific temperature profiles based on their melting points and flow behaviors.

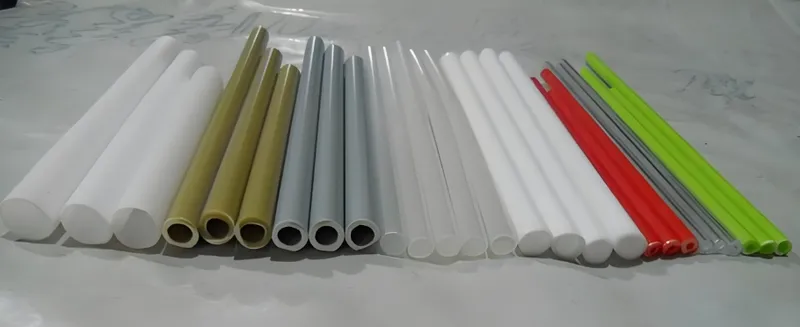

Common Plastics

-

Polyethylene (PE)3: Processed at 150-250°C with a rising profile to ensure complete melting and flow.

-

Polyvinyl Chloride (PVC)4: Extruded at 170-190°C with a flat profile to avoid thermal degradation.

- Polypropylene (PP): Requires 200-250°C, often with a peak profile for optimal viscosity.

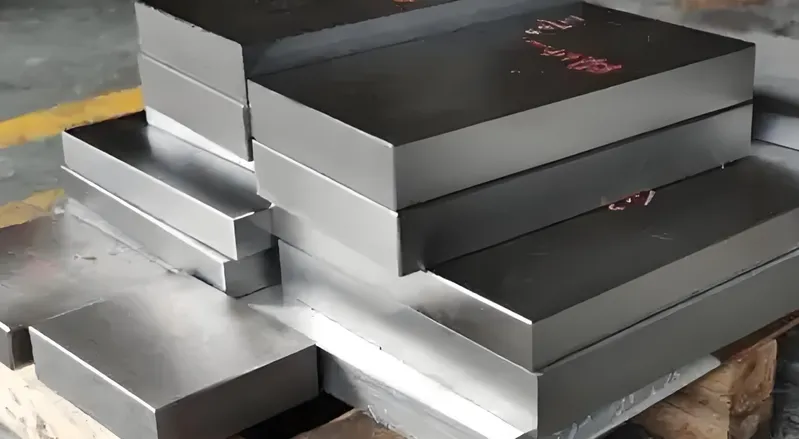

Metals

- Aluminum: Hot extruded at 350-500°C using an isothermal (constant) profile for uniform quality.

- Steel: Needs 900-1200°C with a peak profile to manage high flow stress.

All materials use identical temperature profiles.False

Each material’s thermal properties necessitate unique settings for effective extrusion.

PVC requires lower temperatures than polyethylene.True

PVC’s heat sensitivity demands lower settings to prevent degradation.

What Are the Steps to Adjust Temperature Profiles?

Adjusting temperature profiles is a methodical process that balances manufacturer guidelines with real-time observations to achieve the best results.

Start with recommended settings, monitor the process, and adjust incrementally (5-10°C) based on product quality to optimize extrusion.

Step 1: Use Manufacturer Guidelines

Begin with the temperature settings suggested by the material supplier. These provide a reliable baseline for most applications.

Step 2: Observe the Process

Watch the extrusion5 closely—check the material’s flow, the extrudate’s appearance, and signs of defects like warping or rough surfaces. This feedback guides your adjustments.

Step 3: Adjust Incrementally

Make small changes—typically 5-10°C—in the relevant zone:

-

Poor melting? Increase barrel zone temperatures.

-

Rough surface? Tweak the die zone.

Step 4: Test and Refine

Run a test after each adjustment, assess the outcome, and refine further until the product meets quality standards.

Large temperature changes are best for fine-tuning.False

Small adjustments prevent overshooting and introducing new defects.

Monitoring is critical for effective adjustments.True

Real-time observation ensures timely corrections and consistent quality.

What Challenges Arise in Temperature Profile Adjustments?

Fine-tuning temperature profiles isn’t without hurdles, especially when balancing material behavior and process efficiency.

Challenges include preventing degradation, ensuring uniform melting, and optimizing energy use while maintaining quality.

Material Degradation

Heat-sensitive materials like PVC can degrade if temperatures exceed safe limits, requiring precise control to avoid discoloration or breakdown.

Uniform Melting

Uneven melting can cause lumps or voids. A well-designed profile with gradual temperature increases helps maintain consistency.

Energy Efficiency

Higher temperatures improve flow but raise energy costs. The goal is to find the lowest effective settings that still deliver quality.

Higher temperatures always enhance extrusion quality.False

Excessive heat can degrade materials and waste energy, so optimization is key.

Fine-tuning profiles improves energy efficiency.True

Optimized settings reduce unnecessary heating, cutting costs without sacrificing quality.

How Do Temperature Profiles Vary by Industry?

Industries like construction and automotive have distinct extrusion needs, influencing how temperature profiles are configured.

Construction, automotive, packaging, and electronics each require tailored temperature profiles to meet specific product demands.

Automotive

Components like trims need consistent profiles—often isothermal for metals (350-500°C for aluminum)—to maintain integrity.

Construction

For pipes and frames, rising profiles (e.g., 150-250°C for plastics) ensure strength and dimensional stability.

Packaging

Films and containers use profiles that balance flow and cooling (e.g., 200-250°C for PP) for uniform thickness.

Electronics

Heat sinks demand precision, with tight control (e.g., 350-500°C for aluminum) to ensure thermal performance.

Temperature profiles are identical across industries.False

Industry-specific requirements drive unique temperature settings.

Rising profiles are common in construction for plastics.True

They ensure thorough melting for robust structural products.

What are Some Practical Tips for Optimizing Temperature Profiles?

Here are actionable strategies to enhance your extrusion process6:

-

Keep the Feed Zone Cool: Avoid premature melting by setting it below the softening point.

-

Increase Gradually: Ramp up barrel temperatures to melt material evenly.

-

Use a Melt Probe: Measure the material’s internal temperature for precision.

-

Adjust in Small Steps: Limit changes to 5-10°C to maintain control.

-

Account for Environment: Adjust for humidity or ambient temperature as needed.

Ambient conditions don’t affect extrusion.False

Humidity and room temperature can influence material behavior and settings.

A melt probe improves temperature accuracy.True

It provides real-time data for precise profile adjustments.

Conclusion

Mastering temperature profiles is vital for optimal extrusion, ensuring high-quality products across industries. By understanding the roles of each extruder zone, tailoring settings to your material, and refining based on observation, you can achieve consistent results efficiently.

-

Exploring this resource will provide you with expert insights and techniques to optimize your extrusion process effectively. ↩

-

Learning about the feed zone's function will enhance your knowledge of material handling and processing in extrusion, ensuring better product quality. ↩

-

Learn about the specific processing temperatures and techniques for PE to ensure optimal results in your extrusion projects. ↩

-

Discover effective strategies to avoid degradation in PVC, ensuring high-quality extrudates and efficient production. ↩

-

Exploring best practices in extrusion can enhance your understanding and improve your production quality ↩

-

This link will help you discover common challenges in extrusion and effective solutions to improve your production efficiency. ↩