Artificial Intelligence (AI) and Machine Learning (ML) are reshaping industries globally, and manufacturing is no exception. In extrusion processes—a cornerstone of producing everything from plastic films to metal pipes—these technologies are driving unprecedented advancements. By optimizing production parameters, enhancing quality control1, and predicting maintenance needs, AI and ML are making extrusion smarter, more efficient, and more sustainable than ever before.

AI and ML revolutionize extrusion by automating process optimization, improving quality assurance, and enabling predictive maintenance2, resulting in higher efficiency and reduced operational costs.

This article explores how AI and ML are transforming extrusion processes, offering insights into their applications, benefits, and future potential. Whether you're a manufacturer seeking innovation or simply curious about smart manufacturing, understanding these technologies is key to staying ahead.

AI can completely replace human operators in extrusion processes.False

While AI automates repetitive tasks and enhances efficiency, human expertise remains essential for strategic oversight and managing unforeseen challenges.

Machine Learning can predict equipment failures before they occur.True

By analyzing historical and real-time data from sensors, ML identifies patterns that signal impending failures, enabling proactive maintenance.

- 1. What are the Common Applications of AI in Extrusion Processes?

- 2. How Does AI Integrate into the Extrusion Workflow?

- 3. What are the Benefits and Challenges of AI in Extrusion?

- 4. How Does AI Compare to Traditional Extrusion Methods?

- 5. Practical Tools: Implementing AI in Extrusion

- 6. Future Trends and Related Technologies in AI for Extrusion

- 7. Conclusion

What are the Common Applications of AI in Extrusion Processes?

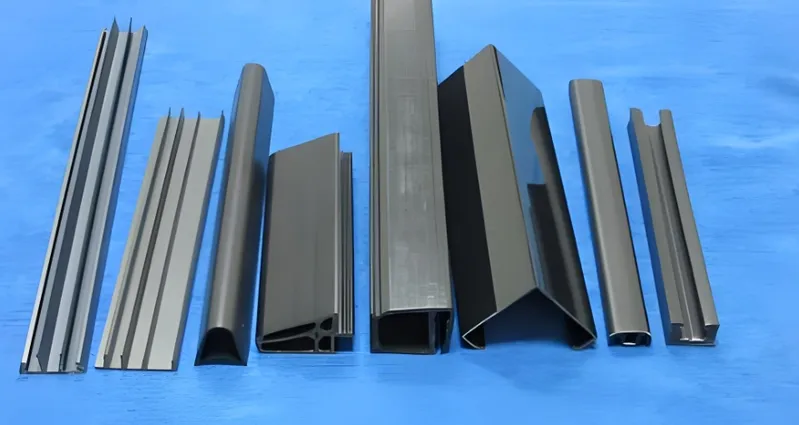

AI is seamlessly integrating into extrusion workflows, enhancing performance across multiple stages and industries.

AI in extrusion is widely applied in process optimization3, quality control, predictive maintenance, and material selection, driving efficiency and minimizing waste.

| Application | Description |

|---|---|

| Process Optimization | AI adjusts parameters like temperature and pressure in real-time for optimal output. |

| Quality Control | ML-powered computer vision detects defects with greater speed and accuracy than humans. |

| Predictive Maintenance | ML analyzes equipment data to predict maintenance needs, reducing downtime. |

| Material Selection | AI recommends materials based on product specs and historical performance data. |

These applications are revolutionizing industries like packaging, automotive, and construction by improving product consistency and reducing resource use, as highlighted in AI and Machine Learning in Manufacturing.

AI reduces material waste in extrusion processes.True

By optimizing parameters and catching defects early, AI ensures fewer substandard products are produced, cutting waste.

AI implementation in extrusion eliminates all manual tasks.False

While AI automates many functions, human input is still required for system setup, data interpretation, and decision-making.

How Does AI Integrate into the Extrusion Workflow?

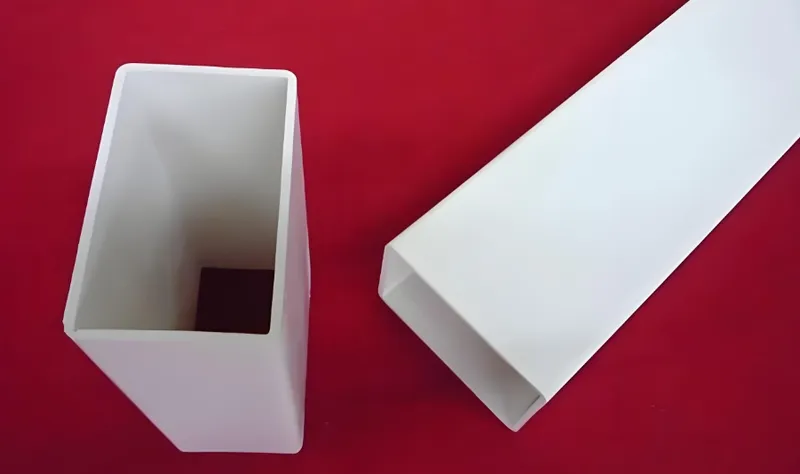

AI enhances every phase of the extrusion process4, from raw material preparation to final product inspection.

AI integrates into extrusion by optimizing material prep, controlling process parameters, monitoring quality, and predicting equipment needs, ensuring consistent, high-quality output.

Key Steps in the AI-Enhanced Workflow

-

Material Preparation: AI analyzes material properties to suggest optimal blends or additives for specific outcomes.

-

Extrusion Control: ML dynamically adjusts variables like screw speed, temperature, and pressure for uniform quality.

-

Quality Monitoring: Computer vision systems inspect extruded products in real-time, flagging defects instantly.

-

Maintenance Prediction: AI processes sensor data to forecast equipment wear, preventing unexpected breakdowns.

AI adapts to various materials by learning from diverse datasets—such as how different polymers respond to temperature or pressure—enabling tailored process control. This adaptability is critical for handling complex extrusion tasks, as noted in Integrating AI in Polymer Extrusion.

AI can optimize extrusion for any material type.True

With proper training data, AI adapts to diverse materials, ensuring precise control across polymers and metals.

AI removes the need for material testing in extrusion.False

While AI streamlines processes, physical testing remains necessary to validate material performance.

What are the Benefits and Challenges of AI in Extrusion?

AI delivers transformative advantages but comes with hurdles that manufacturers must navigate.

AI boosts extrusion efficiency, quality, and cost-effectiveness5, though it faces challenges like high setup costs and data demands.

Benefits

-

Enhanced Efficiency: Real-time adjustments shorten cycle times and reduce energy use.

-

Superior Quality: Automated monitoring ensures fewer defects and consistent output.

-

Cost Reduction: Predictive maintenance and waste reduction lower long-term expenses.

-

Flexibility: AI tailors processes to specific materials and product needs.

Challenges

-

Initial Investment: AI systems require significant upfront costs for hardware, software, and training.

-

Data Dependency: ML models need extensive, high-quality data to perform effectively.

-

Integration Complexity: Retrofitting AI into existing extrusion lines can be technically demanding.

-

Workforce Impact: Automation may shift job roles, requiring reskilling for data-driven tasks.

These dynamics are shaping the adoption of AI in manufacturing, as explored in AI and ML in Manufacturing.

AI in extrusion yields significant long-term savings.True

Reduced waste, downtime, and energy use translate into substantial cost benefits over time.

AI integration in extrusion is simple and inexpensive.False

High costs and technical expertise are prerequisites for effective AI deployment.

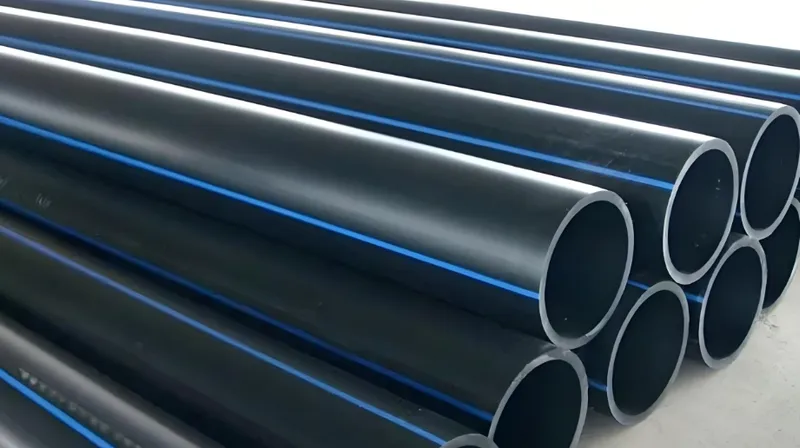

How Does AI Compare to Traditional Extrusion Methods?

AI-powered extrusion outpaces traditional approaches by automating critical functions and improving precision.

AI automates parameter control, quality checks, and maintenance planning6, outperforming manual methods in efficiency and accuracy.

| Aspect | Traditional Extrusion | AI-Enhanced Extrusion |

|---|---|---|

| Parameter Adjustment | Manual, experience-based | Automated, data-driven |

| Quality Control | Human inspection, slower | Computer vision, near-instant |

| Maintenance | Reactive, schedule-based | Predictive, proactive |

| Material Selection | Trial-and-error or supplier data | AI-guided, performance-based |

This shift enhances productivity and product quality, aligning with trends outlined in Types of Extrusion Processes.

Practical Tools: Implementing AI in Extrusion

Ready to bring AI into your extrusion operations? Here’s a practical guide to get started.

Checklist for AI Implementation

-

Identify Goals: Pinpoint areas for improvement, like defect reduction or process speed.

-

Gather Data: Collect historical and real-time data to train AI models.

-

Select Tools: Choose AI software or platforms suited to your needs and budget.

-

Train Staff: Equip your team with skills to operate and interpret AI systems.

-

Test Small: Launch a pilot project to refine the integration.

-

Optimize Continuously: Monitor results and tweak models for sustained performance.

Decision-Making Guide

-

Goal: Fewer Defects? Use computer vision for quality control.

-

Goal: Less Downtime? Prioritize predictive maintenance tools7.

-

Goal: Higher Efficiency? Focus on AI-driven process optimization.

Future Trends and Related Technologies in AI for Extrusion

AI in extrusion8 is part of a broader smart manufacturing ecosystem9, poised for further evolution.

Future advancements include deeper IoT integration, robotics automation, and big data analytics, amplifying AI’s impact on extrusion.

-

IoT Synergy: Real-time sensor data enhances AI’s process control capabilities.

-

Robotics: Automated material handling pairs with AI for end-to-end efficiency.

-

Big Data: Large-scale analytics drive continuous process refinement.

These innovations promise smarter, more autonomous extrusion lines, as discussed in AI and ML in Manufacturing.

Conclusion

AI and Machine Learning are more than buzzwords—they’re powerful tools revolutionizing extrusion processes. By optimizing workflows, ensuring quality, and anticipating maintenance, they deliver efficiency and sustainability gains that traditional methods can’t match. As smart manufacturing evolves, embracing AI will be essential for manufacturers aiming to innovate and thrive.

-

Discover the impact of AI on quality control processes and how it can improve product consistency and reduce defects. ↩

-

Learn how predictive maintenance can minimize downtime and enhance operational efficiency in manufacturing processes. ↩

-

Explore how process optimization can enhance efficiency and reduce costs in manufacturing through AI applications. ↩

-

Explore how AI transforms each stage of extrusion, improving efficiency and quality in manufacturing processes. ↩

-

Discover the significant advantages AI brings to extrusion, including efficiency, quality, and cost savings. ↩

-

Learn how AI automation in extrusion leads to improved precision and productivity over traditional methods. ↩

-

Learn about predictive maintenance tools and their role in minimizing downtime and optimizing production processes. ↩

-

Explore how AI can transform extrusion processes, enhancing efficiency and quality control in manufacturing. ↩

-

Discover the concept of smart manufacturing ecosystems and how they integrate technologies for improved operational performance. ↩