Plastic extrusion, a vital manufacturing process for producing continuous profiles like pipes, sheets, and films, is undergoing a significant transformation thanks to Industry 4.01. Known as the fourth industrial revolution, Industry 4.0 integrates advanced digital technologies—such as artificial intelligence (AI), the Internet of Things (IoT), and data analytics—into traditional manufacturing, creating "smart factories" that optimize production and enhance efficiency.

Industry 4.0 enhances plastic extrusion2 by leveraging AI, IoT, and digital twins to improve efficiency, reduce waste, and elevate quality control, though it demands substantial investment and expertise.

This blog post delves into how Industry 4.0 is reshaping plastic extrusion, exploring its technologies, benefits, challenges, and real-world applications. Whether you're a manufacturer seeking to modernize or a decision-maker evaluating its potential, this guide offers valuable insights into this industrial evolution.

Industry 4.0 eliminates the need for human operators in plastic extrusion.False

While it increases automation, human oversight remains critical for decision-making, troubleshooting, and safety.

Industry 4.0 can significantly reduce waste in plastic extrusion.True

Real-time monitoring and AI adjustments optimize the process, minimizing material waste and boosting efficiency.

- 1. What Is Plastic Extrusion and How Does Industry 4.0 Integrate?

- 2. What Are the Key Technologies Driving Industry 4.0 in Plastic Extrusion?

- 3. What Are the Benefits of Industry 4.0 in Plastic Extrusion?

- 4. What Are the Challenges of Industry 4.0 in Plastic Extrusion?

- 5. How Do Traditional and Industry 4.0 Extrusion Compare?

- 6. What Are Real-World Examples of Industry 4.0 in Plastic Extrusion?

- 7. What Are the Future Trends in Industry 4.0 for Plastic Extrusion?

- 8. Conclusion

What Is Plastic Extrusion and How Does Industry 4.0 Integrate?

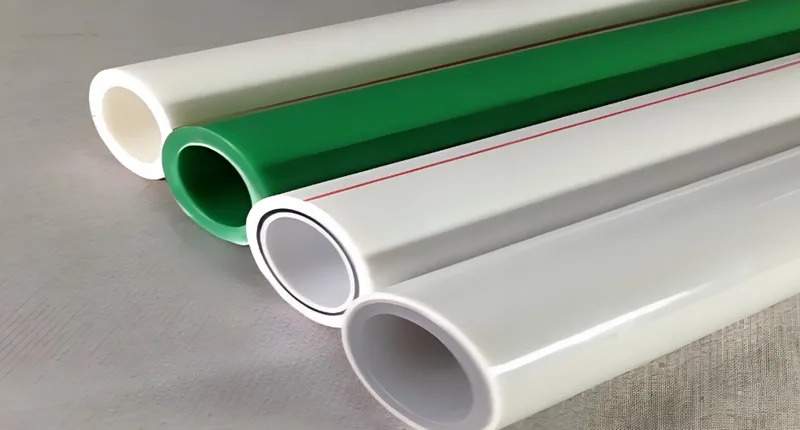

Plastic extrusion involves melting raw plastic materials—like polyethylene (PE) or polyvinyl chloride (PVC)—and shaping them into continuous profiles through a die. Widely used in industries such as packaging, construction, and automotive, it’s prized for its ability to produce uniform, high-volume products efficiently.

Industry 4.0 integrates IoT3, AI, and digital twins into plastic extrusion, enabling real-time data analysis, predictive maintenance, and process optimization for enhanced performance.

The Basics of Plastic Extrusion

In traditional extrusion, plastic pellets are fed into a heated barrel, melted by a rotating screw, and forced through a die to form shapes like tubes or sheets. The process is continuous, making it ideal for mass production, but it often relies on manual adjustments and scheduled maintenance.

Industry 4.0’s Role in Extrusion

Industry 4.0 transforms this process by introducing digital technologies that make extrusion smarter and more responsive:

-

IoT Sensors4: Monitor parameters like temperature and pressure in real time.

-

AI Algorithms5: Analyze data to optimize settings and predict issues.

-

Digital Twins: Simulate the extrusion process virtually for testing and refinement.

-

Predictive Maintenance6: Anticipate equipment needs to prevent downtime.

These advancements create a connected, intelligent system that adapts to changing conditions and improves overall production outcomes.

Industry 4.0 makes plastic extrusion fully automated.False

Automation is enhanced, but human expertise is still required for complex tasks and system management.

Digital twins are essential for Industry 4.0 in plastic extrusion.False

While valuable, digital twins are one of many tools; IoT and AI are also pivotal.

What Are the Key Technologies Driving Industry 4.0 in Plastic Extrusion?

Several cutting-edge technologies underpin Industry 4.0’s impact on plastic extrusion, working together to create a more efficient and precise process.

IoT, AI, digital twins, and predictive maintenance drive Industry 4.0 in plastic extrusion, offering real-time control, optimization, and reduced downtime.

| Technology | Function in Extrusion | Benefit |

|---|---|---|

| IoT Sensors | Track temperature, pressure, speed | Real-time process adjustments |

| AI Algorithms | Optimize settings, detect anomalies | Enhanced efficiency and quality |

| Digital Twins | Simulate extrusion scenarios | Faster innovation, less risk |

| Predictive Maintenance | Predict equipment servicing needs | Reduced downtime and costs |

IoT Sensors: Real-Time Monitoring

IoT sensors embedded in extrusion machines collect data on critical variables, transmitting it to a central system for immediate analysis and adjustments, ensuring consistent performance.

AI: Intelligent Optimization

AI processes sensor data to identify patterns, predict defects, and adjust machine parameters autonomously, reducing energy use and improving product quality.

Digital Twins: Virtual Simulations

Digital twins create virtual models of the extrusion process, allowing manufacturers to test changes—like new materials or settings—without halting production, minimizing errors and costs.

Predictive Maintenance: Proactive Care

Using AI-driven analytics, predictive maintenance forecasts when machines need servicing, preventing unexpected failures and extending equipment life.

IoT sensors are the most critical Industry 4.0 technology in extrusion.False

IoT is vital, but AI and other tools are equally essential for comprehensive optimization.

Predictive maintenance reduces operational costs.True

By avoiding breakdowns, it lowers repair expenses and improves uptime.

What Are the Benefits of Industry 4.0 in Plastic Extrusion?

Adopting Industry 4.0 technologies in plastic extrusion delivers a range of advantages that enhance competitiveness and sustainability.

Benefits include increased efficiency, reduced waste, improved quality, and greater production flexibility.

Boosted Efficiency and Productivity

Real-time data and AI optimization enable faster, more efficient production cycles, allowing manufacturers to meet demand without compromising quality.

Lower Waste and Costs

Industry 4.0 minimizes material waste by detecting and correcting issues early, reducing scrap rates and lowering raw material expenses.

Enhanced Quality Control

Continuous monitoring ensures tighter tolerances and fewer defects, critical for applications requiring precision, such as medical or automotive components.

Flexible Customization

Smart systems allow quick adjustments to produce small batches or customized profiles with minimal downtime, meeting diverse market needs.

Industry 4.0 ensures zero-defect production in extrusion.False

It reduces defects significantly, but material variations can still pose challenges.

Industry 4.0 leads to long-term cost savings.True

Efficiency, waste reduction, and predictive maintenance lower overall costs over time.

What Are the Challenges of Industry 4.0 in Plastic Extrusion?

Despite its advantages, implementing Industry 4.0 in plastic extrusion comes with hurdles that manufacturers must address.

Challenges include high costs7, workforce training needs8, cybersecurity risks9, and legacy system integration.

Significant Initial Investment

New equipment, software, and training require substantial upfront costs, which may deter smaller firms, though scalable solutions are emerging.

Need for Skilled Workers

Managing smart systems demands expertise in both extrusion and digital technologies, necessitating training or new hires.

Cybersecurity Concerns

Increased connectivity heightens the risk of cyberattacks, requiring robust security measures to protect data and operations.

Legacy System Compatibility

Older extrusion equipment may not integrate easily with modern technologies, requiring costly retrofits or replacements.

Small companies cannot adopt Industry 4.0 in extrusion.False

Scalable solutions and ROI potential make it viable for all sizes, despite initial costs.

Cybersecurity is a minor issue in Industry 4.0.False

Greater connectivity increases cyber risks, making security a top priority.

How Do Traditional and Industry 4.0 Extrusion Compare?

Comparing traditional and Industry 4.0-enhanced extrusion highlights the transformative power of smart technologies.

Traditional extrusion uses manual controls and fixed schedules, while Industry 4.0 offers real-time, adaptive, and predictive capabilities.

| Aspect | Traditional Extrusion | Industry 4.0 Extrusion |

|---|---|---|

| Quality Control | Manual, post-production | Real-time, automated |

| Waste Management | Reactive adjustments | Predictive prevention |

| Production Speed | Fixed settings | Adaptive optimization |

| Maintenance | Scheduled or reactive | Predictive, data-driven |

| Customization | Limited, time-intensive | Flexible, rapid adjustments |

From Reactive to Proactive Operations

Traditional methods rely on after-the-fact inspections, while Industry 4.0 proactively adjusts processes to maintain quality and reduce waste.

Industry 4.0 extrusion is always faster.False

It prioritizes efficiency and quality over sheer speed.

What Are Real-World Examples of Industry 4.0 in Plastic Extrusion?

Leading companies are already reaping the benefits of Industry 4.0 in their extrusion operations.

Siemens and KraussMaffei use IoT and AI to enhance extrusion efficiency, quality, and sustainability.

Siemens: IoT-Enabled Extrusion

Siemens employs IoT to monitor extrusion lines remotely, optimizing energy use and reducing waste, as detailed on their website.

KraussMaffei: AI Quality Control

KraussMaffei integrates AI to detect and correct anomalies in real time, improving consistency, as showcased on their site.

Only large firms benefit from Industry 4.0 in extrusion.False

SMEs can also adopt tailored solutions with significant advantages.

What Are the Future Trends in Industry 4.0 for Plastic Extrusion?

The future promises even greater advancements in plastic extrusion through Industry 4.0.

Trends include autonomous AI systems, sustainability focus, and collaborative robots enhancing extrusion processes.

Autonomous Production

AI may soon manage entire extrusion lines, learning and optimizing independently for maximum efficiency.

Sustainability Integration

Technologies will prioritize energy efficiency and recycling, aligning with circular economy goals.

Collaborative Robots (Cobots)

Cobots will assist with tasks like material handling, boosting productivity alongside human workers.

Industry 4.0 will enhance sustainability in extrusion.True

Optimized resource use and waste reduction support eco-friendly practices.

Conclusion

Industry 4.0 is revolutionizing plastic extrusion, offering smarter, more efficient, and sustainable production through technologies like IoT, AI, and digital twins. While challenges like cost and training persist, the long-term gains in quality, flexibility, and cost savings are undeniable. As these technologies advance, plastic extrusion will continue to evolve, meeting the demands of a dynamic industrial landscape.

Industry 4.0 is essential for extrusion’s future.True

It enables manufacturers to meet rising demands for efficiency and customization.

-

Discover how Industry 4.0 is revolutionizing manufacturing with advanced technologies, providing insights into the future of production efficiency. ↩

-

Explore this link to understand the fundamentals of plastic extrusion and its applications in various industries, enhancing your knowledge of manufacturing processes. ↩

-

Learn about the impact of IoT on manufacturing processes and how it contributes to smarter production systems, optimizing efficiency and quality. ↩

-

Explore how IoT sensors enhance real-time monitoring and improve extrusion processes, ensuring efficiency and quality. ↩

-

Discover the role of AI in optimizing settings and enhancing product quality in extrusion, leading to better efficiency. ↩

-

Learn about predictive maintenance and how it can reduce downtime and costs in manufacturing processes, including extrusion. ↩

-

Understanding the financial implications can help manufacturers plan better and find cost-effective solutions. ↩

-

Exploring training resources can enhance workforce skills, ensuring successful implementation of smart technologies. ↩

-

Learning about cybersecurity measures is crucial for protecting sensitive data and maintaining operational integrity. ↩