When you make extruded PVC profiles, you have to do a lot of things just right. If you can make them faster, you’ll save money. If you can make them better, you’ll make more money. If you can make them faster and better, you’ll make a lot more money. In this article, we’ll look at how to make extruded PVC profiles faster and better by doing six things.

To improve extruded PVC profiles, focus on six key factors: perfecting the mold, temperature, pressure, speed, quality, and paperwork. Mastering all ensures faster production, better results, and higher profits.

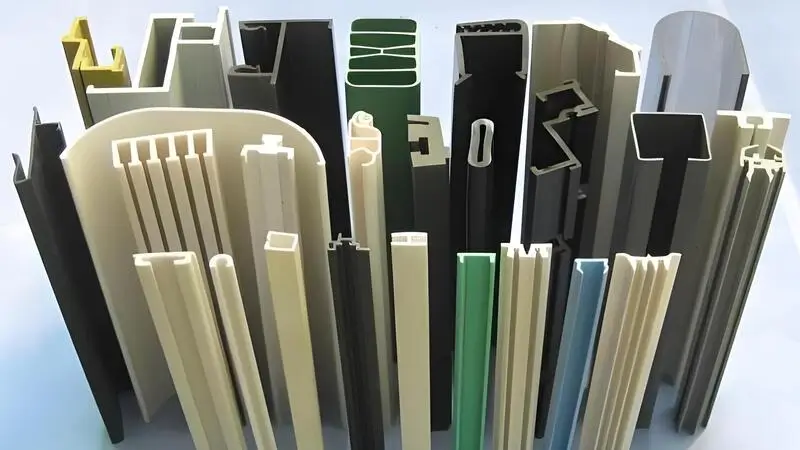

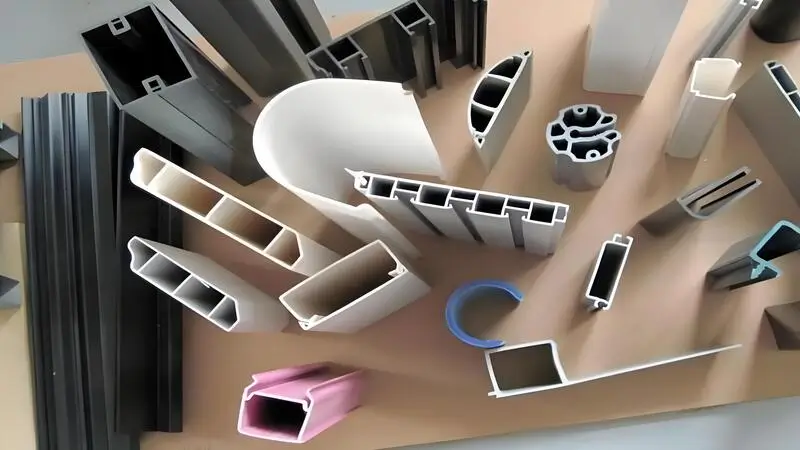

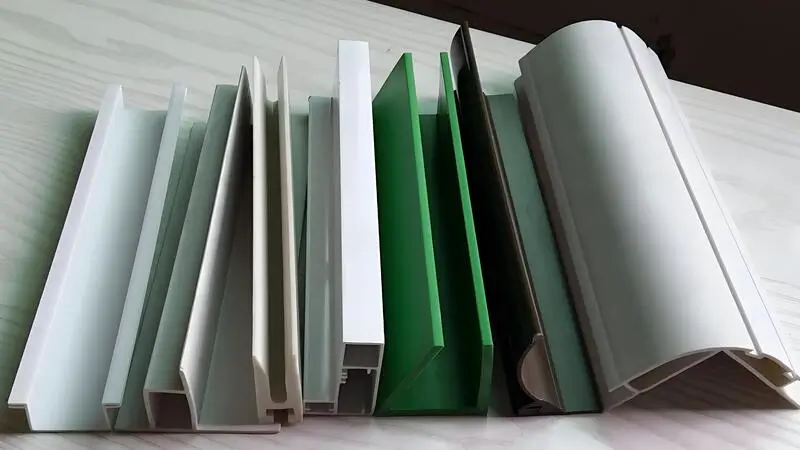

PVC profiles are widely used in construction, window frames, and plumbing systems.True

PVC profiles are durable, weather-resistant, and versatile, making them ideal for various applications.

PVC profiles are limited to indoor applications only.False

PVC profiles can be used both indoors and outdoors, as they are resistant to weathering and UV degradation when treated properly.

- 1. How to optimize the mold design to improve the production efficiency of PVC profiles?

- 2. How to optimize temperature control to improve the productivity of PVC profiles?

- 3. How to optimize pressure to improve the productivity of PVC profiles?

- 4. How to optimize the quality control to improve the production efficiency of PVC profiles?

- 5. How to optimize the working documents to improve the production efficiency of PVC profiles?

- 6. Conclusion

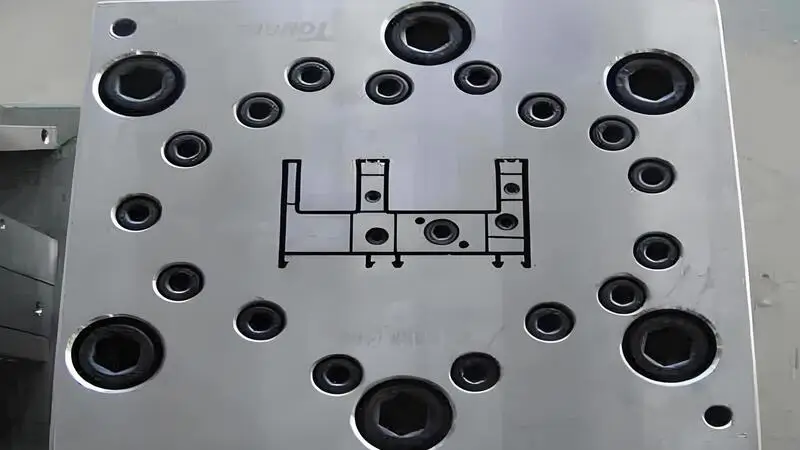

How to optimize the mold design to improve the production efficiency of PVC profiles?

The way you design your mold has a huge impact on how well you can make PVC profiles. If the mold design is reasonable, it will save more time to produce more profiles

Proper mold design enhances production speed, accuracy, and cost-efficiency by enabling faster cooling, reducing maintenance, and allowing for higher output with fewer fixes.

Make your mold cool down faster

The way you cool down your mold makes your profile cool down faster and makes it better. If you design your mold so it cools down fast and use stuff that moves heat around good, you can make your profile cool down the same all the time and make more profiles.

Selecting the right steel for making molds

If you select steel that’s good at being a mold, like steel that can take a lot of heat or stuff that’s made out of more than one thing, you can make your mold last longer and make your profile better.

Optimization of mold structure

By designing the cavity structure, runner design and diversion system reasonably, it can ensure the uniform flow of raw materials in the mold to avoid uneven profile thickness and pulling crack phenomenon.

Mold maintenance

The development of mold maintenance plan, regular maintenance and inspection measures can effectively improve the service life of plastic extrusion molds to ensure the smooth running of the production process and reduce unnecessary production downtime.

Optimizing the mold design improves the production efficiency of PVC profiles.True

Optimizing mold design can lead to better material flow, reduced cycle times, and improved product quality, all of which enhance the overall efficiency of PVC profile production.

Optimizing the mold design does not improve the production efficiency of PVC profiles.False

Failing to optimize the mold design can result in longer cycle times, material wastage, and inconsistent product quality, reducing production efficiency for PVC profiles.

How to optimize temperature control to improve the productivity of PVC profiles?

Temperature control is one of the core factors in the production process of PVC profiles. Precise temperature control not only ensures material flow, but also optimizes the appearance and physical properties of the profile.

Stable production of PVC profiles can be achieved by precisely controlling the temperature of the extruder, the die and the cooling system.

Extruder temperature control

Optimize the temperature setting of the extruder to avoid thermal degradation of the raw material or insufficient flowability caused by too high or too low temperature, which will affect the production efficiency.

Mold Temperature Adjustment

Reasonable adjustment of the heating and cooling temperatures of the molds to avoid hot spots or overheated areas, to ensure a flat surface of the profiles and to reduce product defects.

Cooling System Design

Efficient cooling system design is essential to maintain the stability of PVC profiles. The use of multiple cooling segments and evenly distributed cooling fans can effectively accelerate the molding process.

Temperature Monitoring System

The introduction of an intelligent temperature control system allows for real-time temperature monitoring and regulation to avoid human error and ensure that the temperature is always in the ideal range during the production process.

Optimizing temperature control improves the productivity of PVC profiles.True

Temperature control is crucial in PVC extrusion as it ensures consistent flow and reduces defects, which leads to higher productivity and better quality in the final PVC profiles.

Optimizing temperature control does not affect the productivity of PVC profiles.False

Without proper temperature control, PVC extrusion can experience issues such as uneven cooling, warping, or defects, which ultimately reduce productivity and quality of the profiles.

How to optimize pressure to improve the productivity of PVC profiles?

When we make PVC profiles, the pressure stability is very important for the quality of the profiles. If the pressure is controlled well, the raw material will flow evenly in the mold, and the profiles will be good without any defects.

To make the extrusion process stable, we need to optimize the pressure control system. If the pressure is controlled well, the production will be stable, and the profiles will be good without any defects.

Control the pressure of the extruder

We need to control the pressure of the extruder to make sure the plastic flows evenly. If the pressure is too high or too low, the plastic will not flow evenly, and the profiles will not be good.

Make the pressure of the runners equal

We need to design the runners of the mold well to make sure the pressure of each runner is equal. If the pressure is not equal, the profiles will have some defects, like cracks and bubbles.

Sense and monitor the pressure

We need to use some good pressure sensors to sense the pressure during production. If the pressure is not stable, we need to adjust it immediately.

Optimizing pressure improves the productivity of PVC extrusion profiles.True

By adjusting the pressure during the extrusion process, manufacturers can enhance the flow of the PVC material, reducing defects and improving the overall efficiency of production, resulting in higher output and quality of the profiles.

Optimizing pressure does not improve the productivity of PVC extrusion profiles.False

Optimizing pressure plays a crucial role in improving the flow and consistency of PVC material, thus boosting productivity and ensuring the production of high-quality PVC profiles with minimal defects.

How to optimize the quality control to improve the production efficiency of PVC profiles?

To ensure the stability and consistency of PVC profile production, quality control is necessary. Precise quality control can effectively reduce the number of unqualified products in production and improve overall production efficiency.

Systematic quality control ensures timely identification and resolution of issues, meeting standards and minimizing rework and scrap in each batch of profiles.

Material Inspection

Using standardized raw materials is important to avoid production problems caused by unstable raw material quality. A strict incoming material inspection process is necessary to guarantee production quality.

Process Parameter Monitoring

Monitoring key process parameters such as temperature, pressure, traction speed, etc. in real-time ensures that the process is always in an optimal state and avoids product quality fluctuations.

Quality Inspection

By inspecting the appearance and size of the product during first piece inspection, process inspection, and final inspection, we can detect and reduce the frequency of quality problems in a timely manner.

Quality Traceability and Feedback

Establishing a perfect quality traceability system allows us to quickly trace quality problems back to the extrusion process, find the root cause, and even solve it.

Optimizing quality control can improve the production efficiency of PVC extrusion profiles.True

Improving quality control in PVC extrusion can help reduce defects, enhance material consistency, and streamline the production process, leading to better efficiency and higher output.

Optimizing quality control has no effect on the production efficiency of PVC extrusion profiles.False

Quality control is a key factor in the success of PVC extrusion. Without proper monitoring and adjustments, inefficiencies and defects can increase, reducing overall production efficiency and product quality.

How to optimize the working documents to improve the production efficiency of PVC profiles?

Well-written onsite operation documents can effectively guide production operations and reduce the inefficiency and quality problems caused by improper operation.

Ensure clear operating standards and documents for each process to reduce errors and standardize operations.

Standardize Operations

Establish consistent operating procedures and standards so that each operator can follow the procedures and reduce unnecessary operational errors.

Manage Production Records

Record production data for each batch, including temperature, pressure, speed, and other parameters, so that you can track and troubleshoot later.

Safe Operating Procedures

Standardize safety procedures for operators on site. This not only protects employees, but also ensures that the production process is not interrupted by unplanned shutdowns.

Optimizing the working documents can improve the production efficiency of PVC profiles.True

By streamlining processes, clarifying instructions, and ensuring proper communication, optimizing working documents can enhance workflow efficiency, reduce errors, and minimize downtime in PVC profile production.

Optimizing the working documents has no effect on the production efficiency of PVC profiles.False

While the optimization of working documents may not directly alter the physical aspects of production, it plays a key role in improving coordination, reducing waste, and increasing overall production efficiency in PVC profile manufacturing.

Conclusion

Making plastic extruded PVC profiles more efficient to produce is a step-by-step process. Everything from designing the mold to checking the quality has a big effect on how fast you can make things and how good they turn out. If you manage things better and use new technology, you can make the whole line work better, make less waste, make better stuff, and save cost.